Mastering Carbon Emissions in Supply Chain & Logistics

Reducing greenhouse gas emissions is a massive challenge that has reached a critical juncture. Carbon dioxide (CO2) levels are a significant driver of climate change, posing severe environmental and health risks. In 2023, the global average CO2 concentration reached a concerning record of 420.0 parts per million (ppm), a rise that threatens to push global temperatures beyond safe limits. Addressing this issue is vital for stabilizing the climate, protecting ecosystems, improving logistics efficiency, achieving cost savings, and ensuring a healthier planet for future generations.

Supply chains and logistics play a pivotal role among the various industries contributing to this emissions crisis—such as energy, agriculture, and waste management. The International Energy Agency (IEA) reported that global energy-related CO2 emissions grew by 1.1% in 2023, reaching 37.4 billion tonnes, primarily due to fossil fuel consumption in key sectors. Notably, the transportation sector accounts for approximately 14% of global greenhouse gas emissions, with projections indicating that freight emissions could increase by over 50% by 2050 if current trends continue. By now, logistics professionals are long past the point of research and planning. The time is now to turn net-zero logistics aspirations into action and change the trajectory.

But how do we get there?

This blog covers supply chain and logistics emissions, their impact, the importance of sustainability, and proven ways to reduce carbon emissions.

Co2 Emissions in Supply Chain

As companies worldwide set bold emission-reduction targets, improving supply chain sustainability has become a top priority. Yet, it feels like an uphill battle since supply chains generate up to 60% of global carbon emissions. Due to manufacturing, transportation, and various intermediary processes, supply chains contribute to CO2 emissions.

Many supply chain organizations want to improve their sustainability scores, but limited visibility into supplier practices, technological barriers, and cost considerations to realize decarbonization often create a formidable challenge. MIT’s State of Supply Chain Sustainability 2023 discovered that only 35% of global organizations have established net-zero goals. Within this group, many organizations seem unprepared to meet their self-imposed deadlines for achieving these targets. This highlights a considerable gap between goals to achieve sustainability and readiness, making proactive action essential.

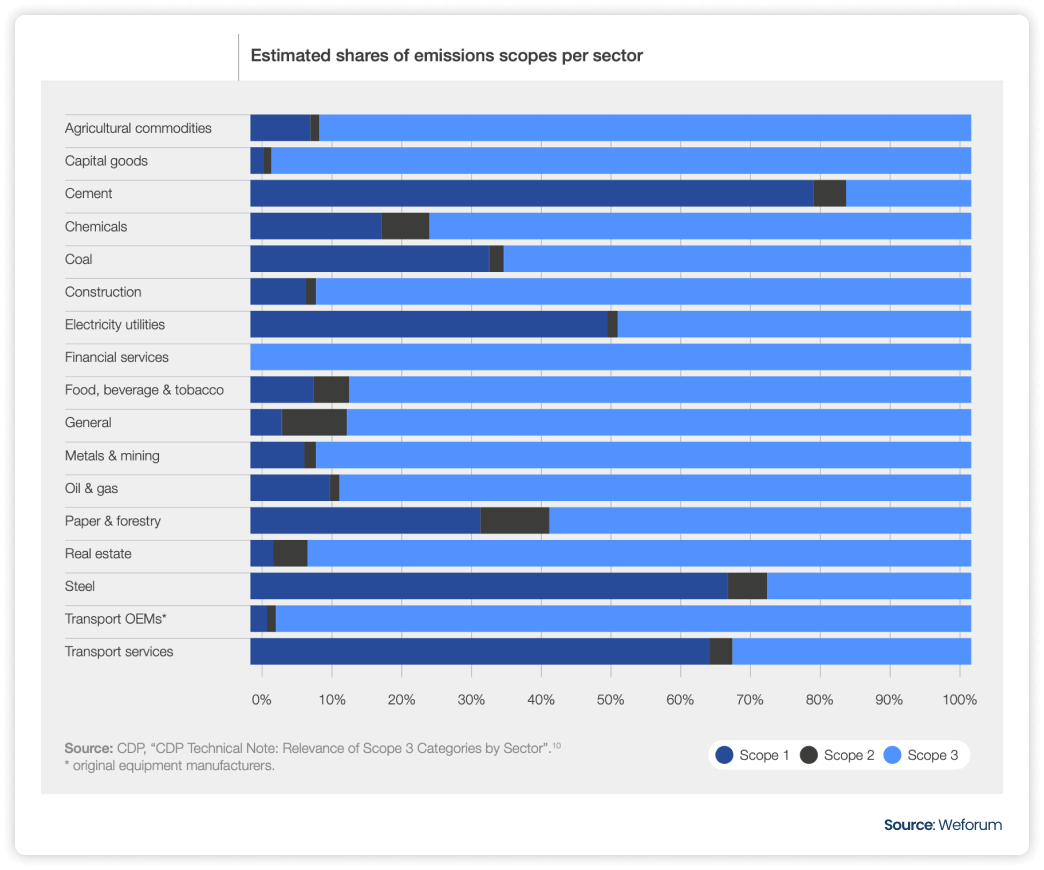

The importance of supply chain sustainability is no longer just about compliance; it has become an essential strategy for corporate responsibility. Supply chains host a staggering portion of global greenhouse gas emissions. Research indicates that Scope 3 supply chain emissions account for 26 times the direct operational emissions (Scope 1 and Scope 2 combined) for many industries. Notably, eight major supply chains—food, fashion construction, freight, fast-moving consumer goods, electronics, automotive production, and professional services—collectively contribute over 50% of all global GHG emissions.

To address carbon emissions effectively, it is essential to differentiate between the three scopes defined by the Greenhouse Gas (GHG) Protocol.

Scope 1: Direct greenhouse emissions from sources owned or controlled by an organization. Examples include emissions from fuel combustion in company-owned vehicles, boilers, or furnaces used for heating, etc.

Scope 2: Indirect GHG emissions associated with purchasing electricity, steam, heat, or cooling. For example, electricity is used in office buildings or manufacturing plants.

Scope 3: An organization is indirectly responsible for emissions up and down its value chain (in other words, supply chain emissions). Purchased goods and services (raw materials for production), transportation and distribution of products, and business travel (air travel for work-related purposes) are typical examples of Scope 3 emissions.

Co2 Emissions in Logistics

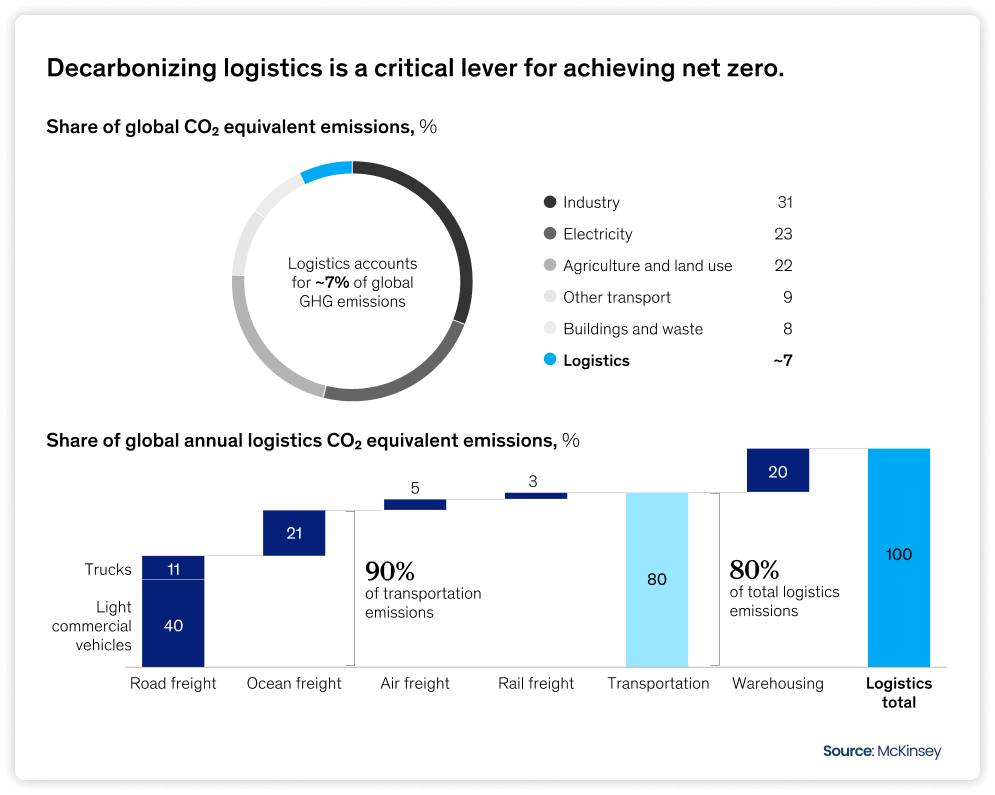

CO2 emissions in the supply chain and logistics are closely related but different concepts. Both contribute significantly to an organization’s overall carbon footprint, yet they arise from different processes within the context of production and distribution. Understanding the dynamics of CO2 emissions across logistics is crucial for organizations aiming to reduce their carbon footprint. Logistics emissions primarily arise from three key areas: transportation, warehousing, and last-mile delivery.

Transportation: This segment includes emissions from different modes of transport, such as trucks, ships, and planes. The transportation sector accounts for approximately 14% of global greenhouse gas emissions, with road freight significantly contributing its share.

Warehousing: Warehouses contribute to heating, cooling, and lighting energy consumption emissions. A McKinsey research states that the logistics industry is responsible for about 7% of global greenhouse gas emissions, with warehousing and freight being significant contributors.

Last-Mile Delivery: This final leg of the delivery process often involves high emissions due to urban traffic congestion and pollution. As e-commerce increases, last-mile delivery emissions are expected to rise considerably.

Why Reducing Carbon Emissions Matters

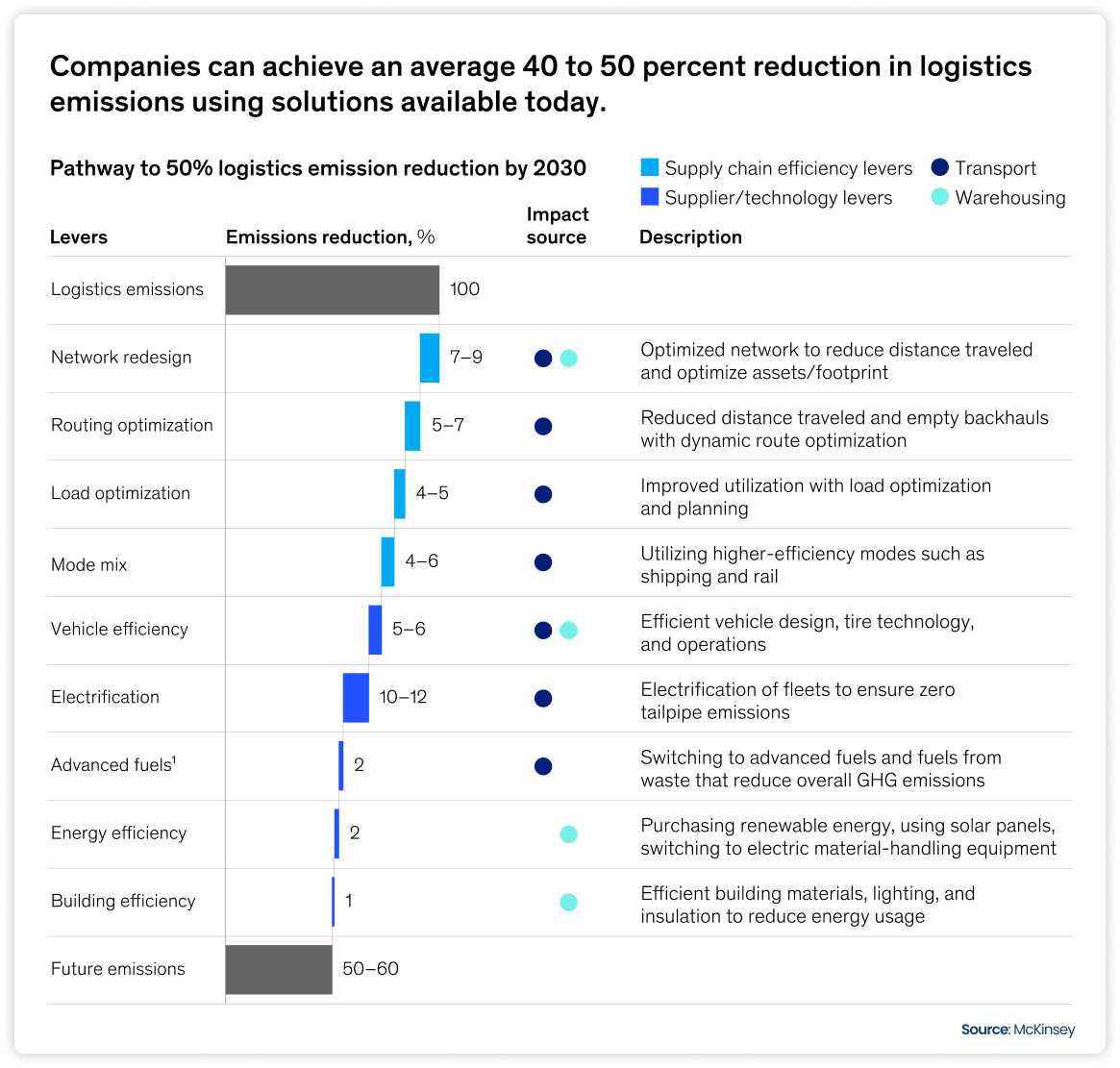

While the future of green logistics looks promising, challenges persist, and progress has been limited. A McKinsey survey revealed that 50% of organizations do not have decarbonization goals. Only a quarter of organizations have set targets and believe they have the means to achieve them; a similar number admit they don’t believe they can achieve their emission reduction targets. As regulatory pressures ramp up and stakeholder expectations increase, businesses that fail to decarbonize may risk falling behind while others pull further ahead in their transition to a greener economy. McKinsey analysis indicates that advanced technology can help reduce emissions by up to 40-50% by 2030. These statistics underscore the importance of adopting sustainable practices to achieve net-zero logistics.

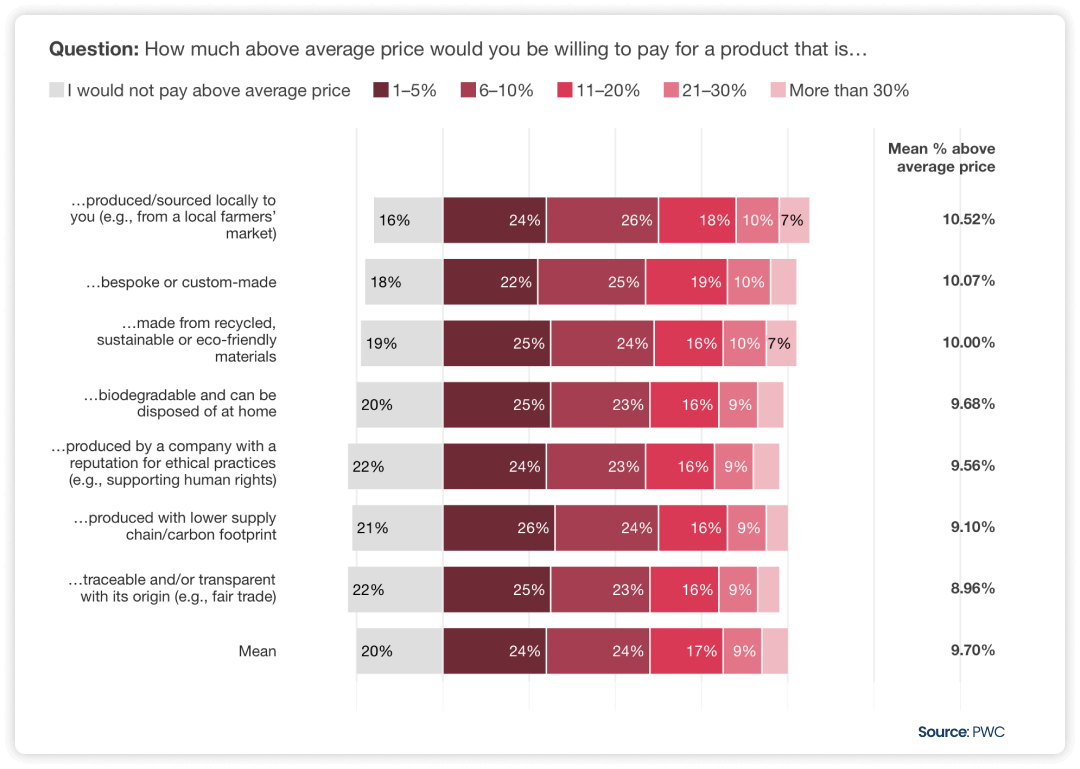

Sustainability in supply chain and logistics is pivotal for environmental conservation and economic viability. Energy-efficient practices reduce ecological impact and achieve long-term financial benefits. For example, organizations that invest in renewable energy sources often see lower energy bills. Also, recent surveys indicate a significant trend among consumers increasingly favoring brands that demonstrate environmental responsibility. Based on PwC’s 2024 Voice of the Consumer Survey, 80% of global consumers would pay more for sustainably produced or sourced goods. This means customers would be willing to pay 9.7 above average price for sustainable products.

As stringent government regulations take shape, businesses that proactively implement sustainable practices will be better poised to comply with such laws. Carbon pricing revenues reached a record of $104 billion in 2023, as stated by the World Bank, determining the growing trend towards the global adaptability of carbon pricing mechanisms.

Strategies to Reduce Carbon Emissions

- Adopt Green Logistics Practices: Research suggests that optimizing energy structures and improving information technology can reduce CO2 emissions substantially. For instance, a study in China found that green logistics practices significantly inhibit carbon intensity in northeastern and western regions of the nation.

- Utilize Low-Emission Vehicles: Transitioning to low-emission vehicles, such as electric or hybrid trucks, can significantly cut emissions associated with freight transportation. Adopting electric vehicles (EVs) is especially beneficial in urban areas where air quality is a constant concern.

- Optimize Transportation Routes: Predictive analytics and artificial intelligence allow organizations to identify the most efficient and viable routes, minimize unnecessary travel, and improve overall operational efficiency.

- Implement Sustainable Packaging Solutions: Using recyclable or biodegradable materials and lighter packaging designs can lower shipping weights and improve fuel efficiency. This not only reduces carbon footprint but also cuts costs over time.

- Invest in Renewables: Switching to renewable energy sources can drastically cut emissions from supply chain operations. Companies can install on-site renewable energy solutions like solar panels or wind turbines. They can also enter into power purchase agreements (PPAs) with renewable energy providers to secure clean energy for operations.

- Shift Modal Transport: Encouraging a modal shift from road to rail transport can lead to lower emissions, as rail has a comparatively smaller carbon footprint than road transport. For example, the European Union’s Fit for 55 initiative aims to accelerate carbon neutrality by promoting such shifts within its member states.

- Enhance Warehouse Efficiency: Warehousing operations contribute to logistics emissions through energy consumption for heating, cooling, lighting, etc. Implementing energy-efficient technologies, such as solar panels and LED lighting, can help reduce greenhouse emissions significantly.

- Adapt Technology for Better Management: Advanced technologies like IoT and telematics can improve fleet management by enabling real-time data on vehicle performance and driving behaviors. This enables logistics companies to monitor idling times, speeding, and other inefficiencies contributing to higher CO2 emissions.

- Collaborate Across the Supply Chain: Companies can collectively reduce their carbon footprints by working together on initiatives such as shared transportation resources or joint sustainability programs. This reduces communication gaps while enhancing operational efficiencies.

Conclusion

With looming regulations and increasing stakeholder pressure, it is high time that businesses prioritize their decarbonization journeys and leverage new-but-proven technologies and robust emissions tracking. Every logistics company faces the complex decision of when and how to begin reducing emissions. Industry leaders are taking proactive steps, positioning themselves to accelerate their decarbonization efforts and gain a competitive edge. When will you?

Whether the shipment is transported by air, ocean, or inland means, Quloi, a robust supply chain visibility platform, provides specific data on the total CO2 emissions generated during shipment. The platform tracks the distance each shipment covers, which is crucial in calculating total emissions. Longer distances increase emissions, so this data helps companies assess logistics efficiency. Quloi ensures stakeholders proactively track shipments, calculate total emissions, and reduce their carbon footprint by enabling real-time shipment visibility.

Check out our whitepaper in the next series to learn more about ways to reduce your logistics emissions to meet decarbonization targets.

Interested to learn more? Book a Demo!