A Snapshot of Packaging Industry in Supply Chain Management

Packaging is a yardstick for global trade and customer satisfaction. Ralph Waldo Emerson once said, “The creation of a thousand forests is in one acorn.” Think about it from the efficiency of mass-produced pallets to the protective capabilities of temperature-controlled boxes; packaging isn’t about convenience; it’s about ensuring products reach their destination safely.

Overview of the Global Packaging Industry

Packaging, a key enabler for everyday consumer life, supports the purchasing journey in retail stores, creates cost-efficient delivery systems for brand owners, and reduces product breakage and waste throughout the supply chain. The packaging industry was valued at $1.14 trillion in 2024 and is estimated to reach $1.38 trillion by 2029. The packaging industry has a strong foothold in North America, Europe, Asia-Pacific, South America, and Middle East and Africa.

The increase in non-biodegradable, non-recyclable plastic packaging has led to a spike in CO2 emissions, potentially acting as a growth deterrent. In response, major players such as Amazon, Google, and Tetrapak have come forward to achieve net-zero carbon emissions, a move set to define their future capital investments.

The packaging industry appears fragmented due to the convergence of several trends, but some leaders spearhead the industry including Amcor Group GmbH, Berry Global Group, Inc., International Paper Company, and Mondi Group. Key factors driving the packaging landscape include market penetration levels, advertising expenditures, sustainable competitive advantages driven by innovation, and firm concentration ratios.

Significance of the Packaging Industry in Supply Chain

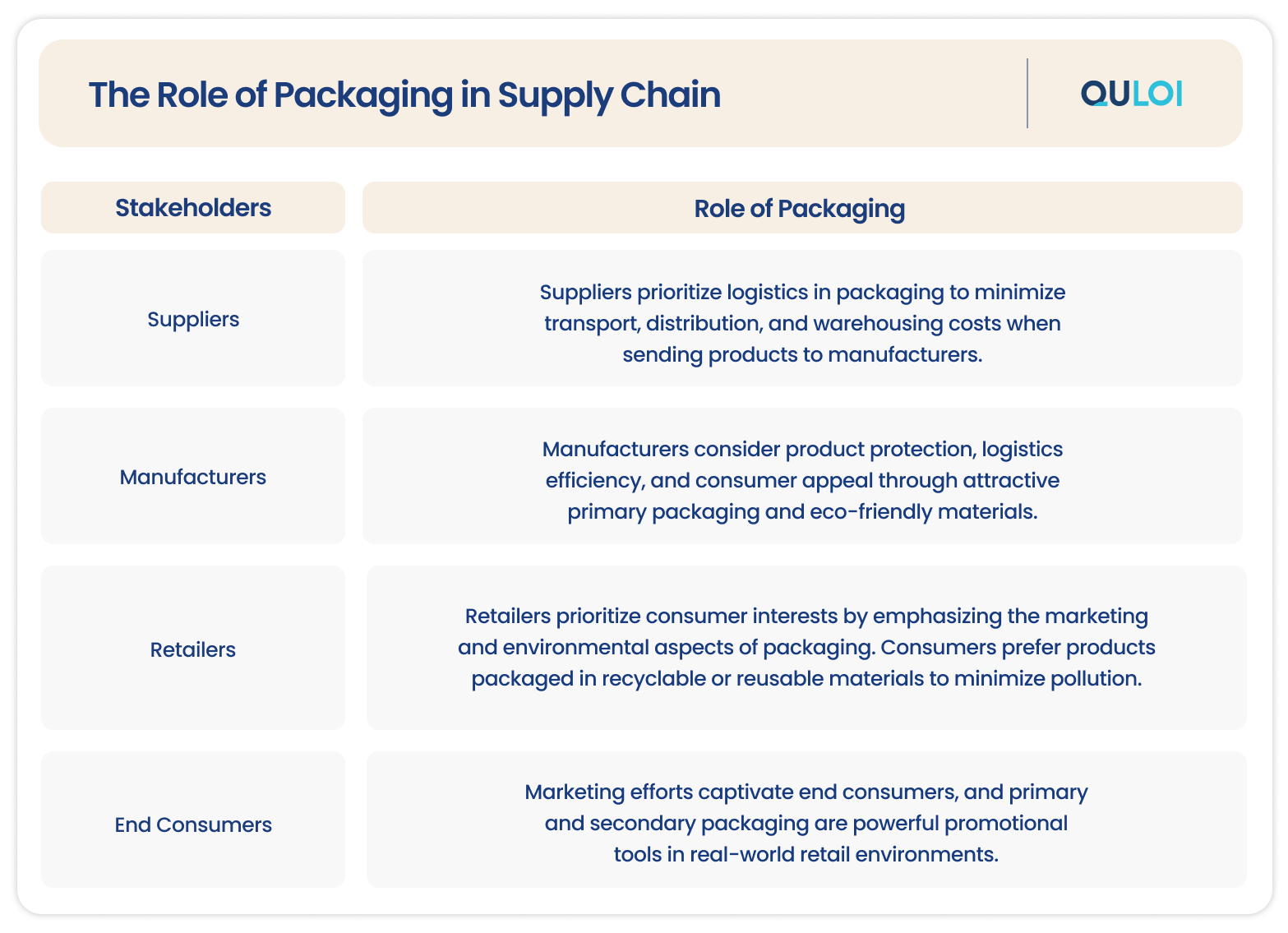

Today’s consumers demand packaging that offers more than mere functionality. Packaging has multiple functions, from protecting the product during handling and storage to transport and preventing contamination and spoilage. Different stakeholders rely on packaging for its specific purposes and benefits.

Protection and Preservation of Products

Product safety is one of the basic packaging functions for both companies and users. An unprotected product could lead to product wastage, negatively impacting the economy and the environment. The right packaging protects products during manufacturing and assembly, storage (within the warehouse), and transport (within the vehicle) from surrounding conditions against loss, perishability, theft, and manipulation of goods. For example, Tetra Pak, a leader in food processing and packaging solutions, uses aseptic technology to preserve perishable goods like milk, juices, butter, etc. This packaging ensures extended product shelf life while maintaining freshness.

Efficient Logisctics and Distribution

Packaging is crucial in optimizing logistics and distribution processes. 80.2% of product returns occur due to damage or breakage. Well-designed packaging solutions minimize storage space requirements, reduce shipping costs, and facilitate easier handling during transportation. E.g. Amazon’s “Frustration-Free Packaging” focuses on reducing packaging waste and improving shipping efficiency, resulting in increased sales and reduced returns.

Enhancing Branding and Consumer Experience

Packaging is a powerful branding tool influencing consumer purchasing decisions. Appealing designs and sustainable materials can differentiate products in a competitive market and foster brand loyalty. Brands that use sleek monochromatic designs and minimalist illustrations stand out in a competitive market. Consider Apple, a global leader, uses minimalistic designs to embrace a user-centered approach.

Environtmental Goals

A McKinsey Packaging Survey revealed that consumers ranked price, quality, and convenience as the most important buying criteria when purchasing a product instead of environmental aspects. Interestingly, the importance of environmental considerations as a key purchasing factor varies based on age group and locality. 37% and 39% of Gen Z and millennial consumers, respectively, and 40% of those living in urban neighborhoods cited environmental impact as an extremely or very important factor when making their buying decisions. By contrast, only 18% of baby boomers and 21% of consumers living in rural areas cited the same.

Regulatory Compliance and Safety Standards

Complying with the Fair Packaging and Labeling Act (FPLA) and other Federal laws and regulations is important to ensure product legality and consumer safety. For instance, in the food industry, regulations govern aspects such as materials used (safety of food contact materials) labeling requirements (e.g., nutritional information, recycling symbols, ingredient declaration), and environmental impact (e.g., limitations on packaging waste).

Supply Chain Challenges Facing the Packaging Industry

Over the past few decades, the global packaging industry has enjoyed healthy growth, driven by new market expansion and changing ownership dynamics, but are plagued by certain challenges:

Raw Material Sourcing and Availability

The packaging industry is highly dependent on the availability of raw materials. In 2023, the Asia-Pacific region dominated the global packaging industry, with a 46.3% share of total volumes. Rigid plastics in packaging consumption have a 31.4% share, followed by flexible packaging at 30.5% and paper & board packaging at 15.2%. This emphasizes the critical need for material sourcing. A Deloitte study claims that material costs for packaging have increased in the past three years due to material shortages, a spike in energy prices, and rising freight costs.

Environmental Regulations

Adhering to stringent environmental regulations requires the packaging industry to invest in compliance practices, which can be costly and resource-intensive. In 2020, Coca-Cola faced a penalty of $3.3 million for failing to comply with California’s bottle recycling law, highlighting the financial repercussions of non-compliance with recycling regulations. Plastic waste from packaging adds toxic pollutants to the water, soil, and air, affecting communities and wildlife. A Capgemini survey reported that 63% of consumers expect brands to share information about sustainable products, while 55% believe stronger sustainability efforts enhance a brand’s positive consumer perception. To obtain this information, 46% of consumers support detailed labels and scannable QR codes on product packaging that provide water, carbon footprint, and product recyclability attributes.

Demand Volatility and Forecasting Accuracy

Unprecedented developments in the packaging industry make forecasting demand and prices difficult. Inaccurate demand forecasting can result in surplus inventory, tying up capital, or stockouts, resulting in lost sales and revenue opportunities. According to McKinsey, implementing AI-driven forecasting in supply chain management can reduce errors, potentially decreasing lost sales and product unavailability by up to 65%, with error reductions between 20% and 50%.

Digitization

The packaging industry has faced multiple challenges due to disconnected systems and processes. Without integrated processes, optimizing the overall packaging for last-mile shipments is difficult. There is a greater need to improve the consumer’s unboxing experience and facilitate easy returns. Digitization in packaging is still in its infancy, making it challenging to drive down costs and gain a competitive edge.

Looking Outside of the Packaging Box with Quloi

While challenges impede the growth of the packaging industry, there are opportunities to preserve value and growth. Leaders who revamp their business models based on innovation, agility, sustainability, collaboration, and resource allocation will stand out from competitors. These elements will be the bridging mechanism needed to minimize waste, reduce costs, ensure sustainability, and improve the packaging product experience through improved materials and design. Quloi, an end-to-end supply chain visibility and collaboration platform, helps you scale your packaging company by enabling real-time visibility, centralizing data and communication channels, and streamlining supplier management.

Book a FREE Demo to learn how to reshape your packaging strategy, drive growth, and capture value.