Supply Chain Lead Time

and It’s Impact on

Performance

Lead times can make or break a company’s bottom line. Picture this: you’re waiting for your favorite pizza, and it takes two hours instead of the promised thirty minutes. Frustrating, right? According to Robert Rodin, Customers want “free, perfect, and now right,” basically, the right component at the right price and time. For manufacturers, their entire business depends on it, and managing lead time is more critical than ever in the current challenging logistics landscape, with geopolitical disruptions, container and truck driver shortages.

What is Lead Time in Supply Chain?

Lead time in supply chain refers to the total time it takes for a product to move through the supply chain, from the time an order is placed until the product is delivered to the end customer. This journey involves several critical stages: procurement, manufacturing, and distribution. Each stage can significantly impact the overall lead time, making it a comprehensive measure of supply chain efficiency.

Lead Time Definition in Supply Chain

Lead time in supply chain management can be broken down into several components:

Order Lead Time: Time taken from the placement of an order until the order is acknowledged by supplier.

Procurement Lead Time: The duration required to source and receive raw materials/semi-processed goods from suppliers. It includes order processing, manufacturing lead time at the supplier’s end, and transit time to the manufacturing facility.

Production Lead Time: The time required to manufacture the product, from the start of production to the completion of the final product. This can be varied depending on:

Made-To-Stock (MTS): Products are ready in the warehouse quickly but require high stock levels.

Assemble-To-Order (ATO): Semi-finished products are assembled before delivery.

Make-To-Order (MTO): Products are manufactured only after receiving the order.

Engineer-To-Order (ETO): Custom products are designed and created from scratch.

Warehouse Processing Time: Includes receiving, picking, packing, and preparing the order for shipment.

Transportation Time: Depends on the mode of transport and any customs delays.

Delivery Lead Time: Time taken to transport the finished product to the end customer or distribution center. This includes handling, loading, transit, and unloading.

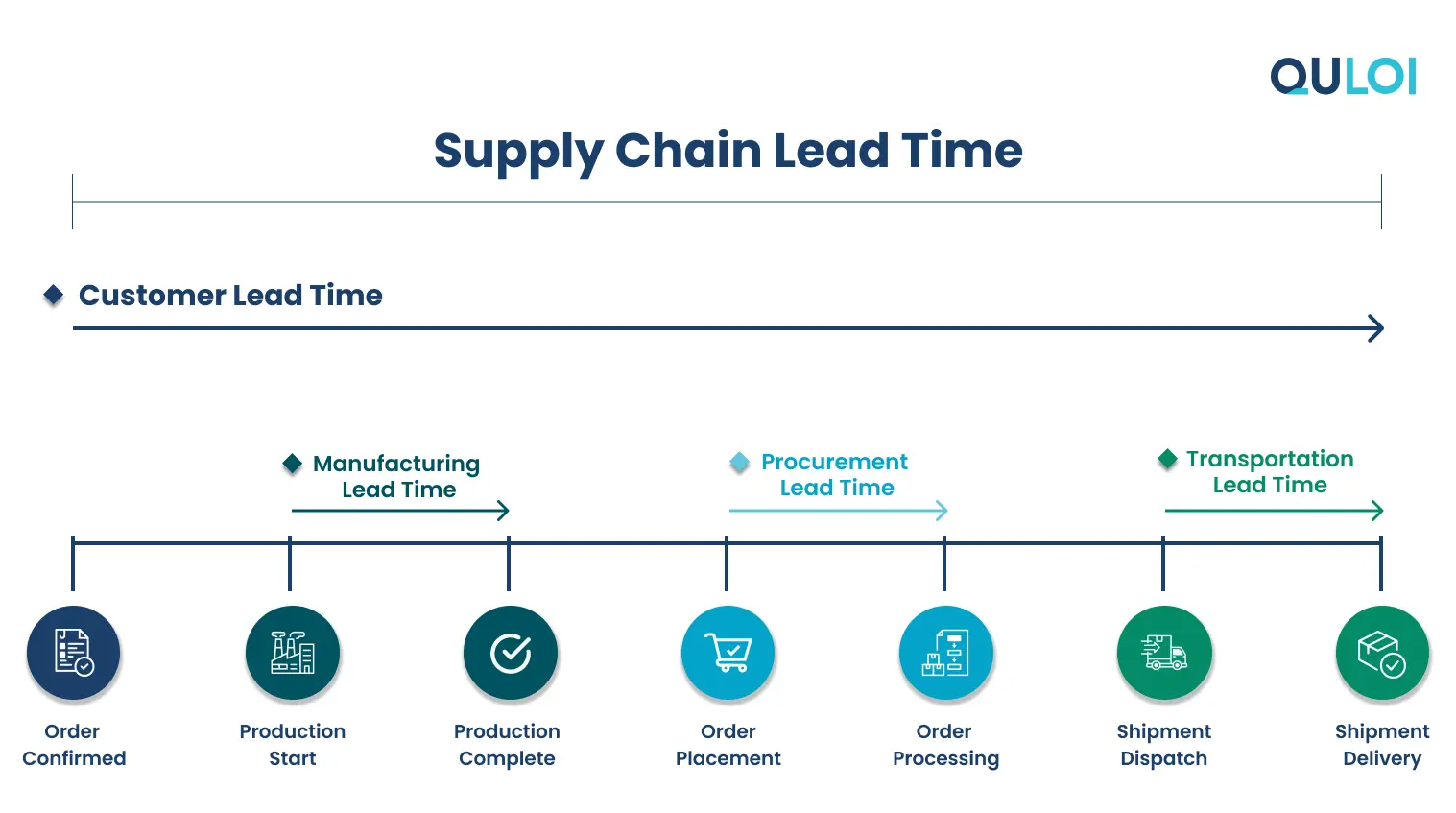

Types of Lead Times in Supply Chain

Lead time isn’t a one-size-fits-all metric; it varies depending on the context and the specific processes involved. Here are some of the main types of lead time in the supply chain:

Manufacturing Lead Time

Lead time in manufacturing describes the amount required to transform raw materials into finished goods ready for distribution. This encompasses the time from when manufacturing begins until the product is completed. This can vary depending on the complexity of the product manufactured and production capacity.

Shipping Lead Time

Shipping lead time represents the time required to deliver goods from the supplier to the recipient. This critical aspect of the supply chain helps companies manage production schedules, inventory controls, and demand forecasting.

Replenishment Lead Time

Replenishment lead time refers to the duration between placing an order and having the product available in inventory again. Adequate replenishment lead time minimizes the need to overstock inventory, ultimately reducing overhead costs.

Supplier Lead Time

This refers to the time suppliers take to deliver materials or components after an order is placed. This can be anything from a few days for local vendors to weeks (or even months!) for overseas shipments.

Customer Lead Time

It is the total time from when a customer places an order until they receive the product. It’s the sum of order lead time, manufacturing lead time, and delivery lead time.

Importance of Lead Time in Supply Chain

The importance of managing lead time effectively cannot be overstated. Here’s why:

Customer Satisfaction: Shorter lead times mean faster deliveries, which enhance customer satisfaction and loyalty. In today’s competitive market, customers expect quick and reliable service. Therefore, managing lead time effectively is crucial for meeting these expectations and maintaining a loyal customer base.

Inventory Management: Efficient lead time management helps maintain optimal inventory levels. Too much inventory ties up capital and increases storage costs, while too little can lead to stockouts and lost sales.

Cost Reduction: Reducing lead times can lower costs across the supply chain. It minimizes holding costs, reduces the need for safety stock, and improves cash flow by speeding up the time from order to payment.

Competitive Advantage: Companies that deliver consistently faster than their competitors gain a significant market advantage. This allows them to respond more quickly to market demands and changes.

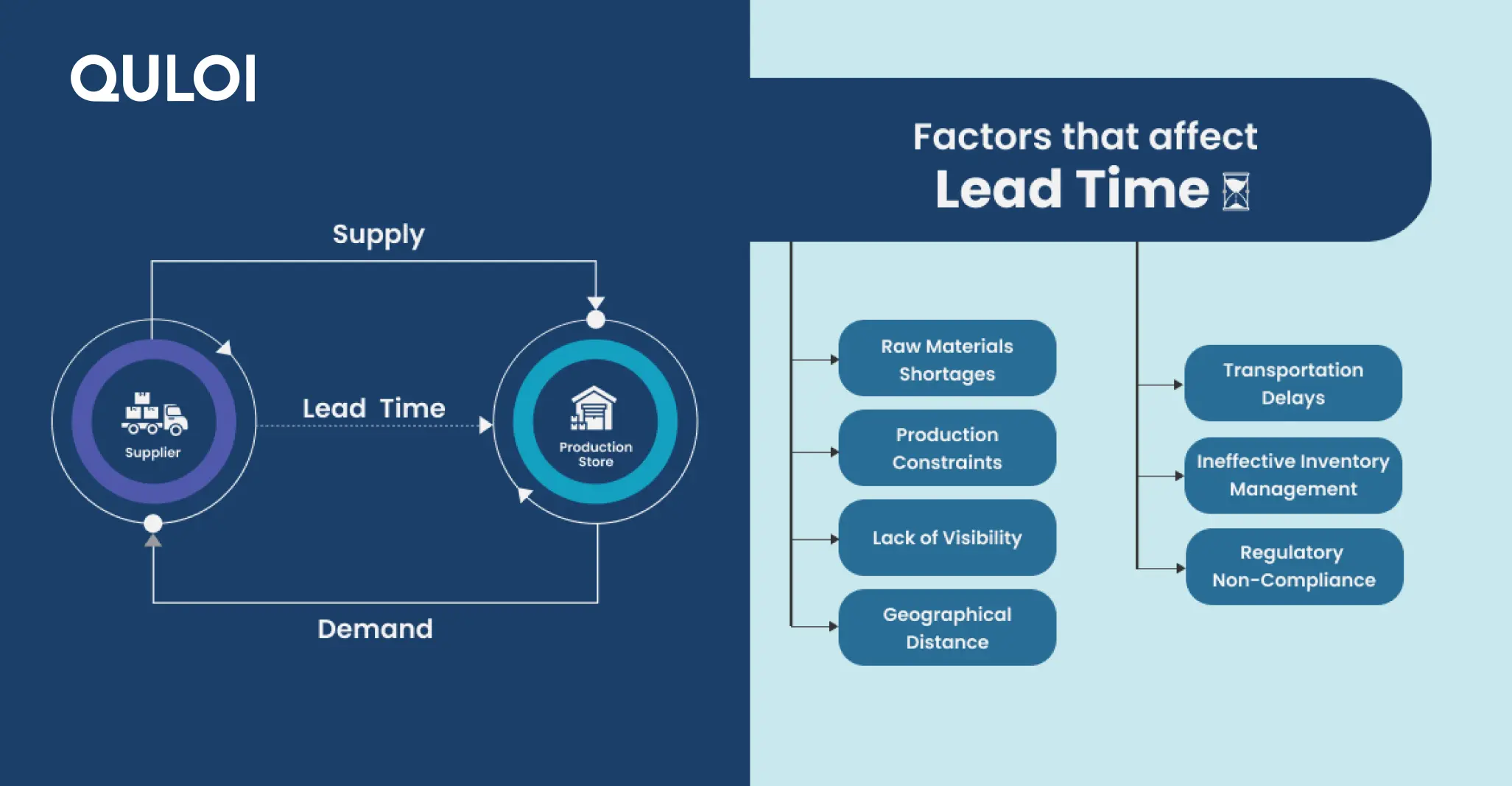

Causes of Longer Lead Times in Supply Chain

Raw materials shortages: With material shortages, manufacturers may not have the required inputs to produce finished goods. This can result in production delays, causing backlogs in orders and longer lead times- impacting the overall supply chain.

Production Constraints: Labor shortages, equipment breakdowns or maintenance, and inefficient processes cause a domino effect, leading to extended lead times. Additionally, high demand can overwhelm production capacity, causing delays in meeting fluctuating demand and resulting in longer lead times.

Lack of Visibility: When real-time information about production schedules, inventory levels, and shipments isn’t readily available, it becomes challenging to align these activities in a coordinated manner. A Deloitte study claimed that 40% of supply chain companies identified late delivery as their biggest problem. Delays in one part of the supply chain result in miscommunication, delays, and ultimately longer lead times.

Geographical Distance: When buyers and suppliers are located in different geographies, communication and coordination become challenging. Time zone differences and language barriers can affect problem-solving processes and decision-making, thereby extending lead time in the supply chain.

Transportation Delays: Transportation delays cause uncertainty in the goods to arrive at their intended destination. This uncertainty can disrupt the supply chain – affecting production schedules, inventory management, and customer expectations. The latest Deloitte research reveals that 53% of the surveyed companies report that supply chain disruptions have a strong to very strong impact on their business. Disruptions impact operational efficiency, causing longer lead times in supply chains.

Ineffective Inventory Management: With inadequate inventory management practices, there’s a higher likelihood of stockouts or excessive inventory levels. Stockouts mean customers must wait for the products to become available again, whereas excess inventory can become obsolete, occupying warehouse space and incurring storage costs. In 2022, eCommerce sellers lost almost $2 trillion to issues related to mismanaged inventory.

Impact of Long Lead Times on Supply Chains

Higher Bullwhip Effect: Longer lead times make the bullwhip effect worse. This happens when an irregular customer demand pattern impacts the product supply, resulting in a chain reaction involving manufacturers, suppliers, and wholesalers. As a result, production planning and procurement processes suffer inefficiencies – causing shipment delays and leading to revenue loss.

Increased Inventory Levels: The longer the lead times, the higher inventory levels are required to buffer against demand and supply gaps. This increases storage and holding costs, straining a company’s budget.

Inaccurate forecasting: Without measuring lead times, accurate demand forecasting becomes a challenge. Companies might produce goods based on inaccurate forecasts, resulting in stockouts or excess inventory. A study performed by Duc, T.T.H.; Luong, H.T.; Kim, Y.D. claimed forecasting inaccuracy is one of the main factors that weaken supply chain performance, leading to either excess inventory or shortages in the supply chain network. This causes operational inefficiencies and financial losses.

Reduced Agility: Usually, the longer the lead time, the harder it becomes for companies to respond to market changes quickly. When companies fail to adjust to their production schedules or cannot adapt to evolving market trends, it reduces agility. As a result, companies cannot navigate unexpected challenges or miss out on capitalizing on emerging opportunities.

How to Calculate Lead Time

Calculating lead time involves summing up a product’s various stages, from order placement to delivery. Here’s a step-by-step guide:

Supply Chain Lead Time Formula

Supply Chain Lead Time = Order Processing Time +Procurement Time + Production Time + Delivery Time

By breaking down the lead time into these components, businesses can identify specific areas where delays occur and address them more effectively.

For instance, if the order processing time is two days, procurement time is five days, production time is seven days, and delivery time is three days, the total lead time would be:

Total Lead Time=2+5+7+3=17 days

How to Reduce Lead Time in Supply Chain

Streamline Communication: Encourage supplier collaboration and modern communication tools to align production schedules, quality standards, and delivery timelines. Create a centralized repository that provides a single source of truth to stay updated and make informed decisions.

Implement Automation and Digitalization: Automate order processing, inventory tracking, and data entry to reduce human errors and accelerate information flow across the supply chain network. Supply chain digitalization helps companies achieve optimized operational performance and ensures accurate lead-time projections to drive result-oriented outcomes.

Update ERP Systems: Ensure you track lead times in your ERP or forecasting systems for accurate inventory and replenishment planning.

Eliminate Outliers: Remove extreme values that can distort average lead time calculations.

Supplier Relationship Management: Building strong relationships with suppliers can pay dividends in reduced lead times. Encourage supplier collaboration, communicate, set expectations, and foster a partnership mentality.

Implement Automation and Digitalization: Automating order processing, inventory tracking, and data entry can significantly reduce human errors and accelerate information flow. It’s the difference between navigating with a paper map and using GPS.

Evaluate Supplier Performance: Supplier evaluations positively influence an organization’s financial performance, focusing on price, quality, delivery, responsiveness, and risk level. Rank suppliers by their lead time, reliability, and stability. Implement penalties or incentives based on lead time performance.

Increase Visibility and Transparency: Real-time visibility into supply chain operations helps identify and resolve bottlenecks.

Efficient Logistics: Optimizing logistics and transportation can reduce delivery times. This might include using faster transportation methods, optimizing delivery routes, or employing logistics partners with robust networks.

Time is Money. Save Both with QULOI

Reducing lead times is like dieting. You want quick results, but sustainable change takes time and discipline. There’s no magic pill – just a series of smart choices that add up over time. And just like dieting, it helps to have a sense of humor about the whole process. After all, in supply chains, as in life, things sometimes go differently than planned.

Quloi‘s innovative-first mile, collaborative supply chain digital platform with a focus on optimized lead time accuracy, responds directly to the needs of manufacturers, suppliers, and freight forwarders. With lead time accuracy, accelerate your order-to-delivery cycles, optimize inventory, and cut operational costs. Boost customer satisfaction by fulfilling customer expectations in promised timelines.

Don’t leave your lead times to chance. Get in touch with our experts and learn more about how Quloi can help you streamline your lead times.

Frequently Asked Questions

What does lead time mean?

Lead time refers to the total duration from placing an order until the product or service is delivered. It includes order processing, procurement, production, and delivery times.

What is the typical lead time in the manufacturing indsutry?

Lead times can vary widely depending on the industry and product. Generally, manufacturing lead times can range from a few days to several weeks.

How can I reduce supplier lead times?

Building strong relationships with reliable suppliers, diversifying your supplier base, and negotiating favorable terms can help reduce supplier lead times.

How can technology help in reducing lead time?

Technology can streamline various processes, from automated order processing and advanced demand forecasting to real-time inventory management and optimized transportation logistics.

What are common pitfalls in lead time management?

Common pitfalls include relying on unreliable suppliers, poor demand forecasting, inefficient inventory management, and lack of coordination between different stages of the supply chain.

What is lead time in shipping?

Shipping lead time refers to the time from when an order is dispatched from the supplier to its arrival at the customer’s location. This includes the time taken for transportation, customs clearance, and last-mile delivery. Imagine you’re importing electronics from China. The shipping lead time would cover the journey across the ocean, the time spent clearing customs, and the final delivery to your warehouse or directly to customers.

Does lead time include shipping?

Lead time covers the entire process from order placement to delivery, incorporating all intermediary steps such as processing, production, and transportation.

What is the difference between lead time and cycle time?

Lead time refers to the total time taken from order placement to delivery, encompassing all supply chain stages. On the other hand, cycle time refers to the time required to complete one production cycle from start to finish.

What does extended lead time mean?

Extended lead time is when the usual lead time is longer than expected, often due to unforeseen delays or complexities in the supply chain. This can be due to complex production processes, supplier delays, logistical challenges, or regulatory compliance issues. Managing this requires flexibility, alternative sourcing strategies, and, often, creative problem-solving.

How to improve lead time?

Improving lead time involves streamlining processes, leveraging technology, and fostering collaboration. For instance, an advanced ERP system can provide real-time visibility into inventory, which manufacturers can use to align their production schedules with supplier deliveries, thus minimizing wait times.