Improve Supplier Performance Using Supplier Scorecards

Supply chains are the lifeblood of any business, and companies are relentlessly pursuing strategies to maximize profitability and uphold the highest quality standards for their products and services. In this pursuit, suppliers play a pivotal role as the linchpin of operations.

Picture your business as a finely tuned machine, with suppliers as the essential gears that keep it running seamlessly. They provide the critical components and services that drive your success. Yet, maintaining these gears in top-notch condition and ensuring peak performance can be a complex challenge.

To meet this challenge head-on, businesses need a powerful tool in their arsenal: comprehensive supplier performance scorecards. These scorecards offer a clear, data-driven perspective on supplier performance, giving companies the insights they need to make informed decisions, boost efficiency, and consistently uphold the highest quality standards throughout their supply chain.

Traditional vs. Comprehensive Supplier Performance Evaluation

For a long time, traditional evaluation methods have been the go-to method for organizations when assessing supplier performance. These methods encompass a range of techniques, including supplier audits, surveys, and qualitative assessments. While these methods have undoubtedly played a crucial role in gauging supplier performance, they are beginning to show their limitations as supply chains evolve and supplier relationships grow more complex.

Traditional supplier evaluation methods come with inherent flaws. Quantitative assessments often rely on data extracted from ERPs or other tools, and this data may not capture all the nuanced information required. Furthermore, transferring this data into spreadsheets can introduce errors, leading to inaccurate evaluations.

On the contrary, qualitative assessments, while valuable, can be susceptible to personal biases, resulting in inconsistent results and hindering data-driven decision-making. Moreover, traditional methods typically provide only snapshots of supplier performance, rendering them ill-suited to the fast-paced supply chain environment. These static evaluations may fail to capture the dynamic nature of supplier relationships and how they impact operational efficiency.

Comprehensive Supplier Performance Evaluation: A Holistic Approach

In response to the limitations of traditional methods, a robust and adaptable solution has emerged: comprehensive supplier performance evaluation through 360-degree scorecards. This approach combines quantitative metrics like delivery timeliness, cost-effectiveness, and quantity accuracy with qualitative dimensions such as product quality, communication effectiveness, collaboration, and adherence to compliance standards. By assessing both “what” (quantitative) and “how” (qualitative), organizations gain a nuanced and accurate understanding of supplier performance.

This approach offers a more faithful reflection of actual supplier performance. It captures aspects like collaboration, communication, and quality—elements often crucial in determining the success of a supplier relationship. By evaluating not just “what” was delivered but “how” it was delivered, organizations can make well-informed decisions that fortify supplier relationships, mitigate risks, and drive operational excellence.

What are Supplier Scorecards?

Comprehensive supplier scorecards or vendor scorecards are structured frameworks that assess and track supplier performance across various dimensions critical to an organization’s objectives. Importantly, they can be applied to businesses of all sizes.

Comprehensive scorecards wield versatility in their application:

Negotiating with Existing Suppliers

Scorecards are compelling tools for highlighting areas where a supplier needs improvement for the business relationship to continue. This can lead to favorable outcomes, including better pricing or more favorable terms for procurement.

Selecting New Suppliers

When deciding whether to collaborate with a potential supplier, scorecards can benchmark their performance against current suppliers, aiding in informed decision-making.

Identifying Potential Hazards

Scorecards are important in identifying risks associated with working with a particular supplier. This encompasses assessing their financial stability, supply chain reliability, product or service quality, and delivery timelines.

Best Supplier Quality Metrics to Track

You can use hundreds of supplier quality metrics to monitor and measure the performance of your suppliers. Tracking all these vendor performance measurement KPIs would be a misuse of time and resources. Instead, focus solely on the key metrics that provide information about how well your suppliers meet your expectations in areas like lead time, order accuracy, cost control, product quality, delivery timeliness, communication, etc. Let us take a closer look at the crucial supplier performance metrics:

Lead Time: High lead time variability is bound to disrupt production schedules, leading to delays and supply chain inefficiencies. The shorter the lead time, the more responsive you can be to market demands and reduce the inventory you need to hold. You can choose suppliers based on their delivery speed and reliability by tracking lead time, helping you stay efficient.

Order Accuracy: You don’t want to receive a package missing the correct order quantities and specifications. Mistakes in orders can result in production delays, increased costs, and poor brand reputation. Monitoring order accuracy makes it easy to identify which suppliers are reliable and which need improvement. This ensures you have the right materials exactly when needed, keeping your production line uninterrupted.

Communication: Communication is a key to smooth supplier relationships. This supplier metric evaluates how timely your suppliers respond to order inquiries, modifications, or issues. Responsive suppliers can adapt to your needs and address problems faster, minimizing downtime and running your operation without hiccups. Tracking this metric ensures that you work with suppliers who are agile and easy to communicate with.

Product Quality: A Forbes survey shows that 70% of consumers are willing to switch brands for a superior-quality product. The quality of goods metric looks at the rate of defective products supplied. High-quality products are important for maintaining your product standards and keeping customers satisfied. By monitoring product quality, you can identify and resolve issues quickly, ensuring your final products are up to mark. This metric helps you avoid costly product recalls and maintains your reputation for quality.

Cost Performance: This metric in the performance management scorecard tracks how your suppliers adhere to agreed-upon costs. It’s not just about finding the cheapest supplier but ensuring value for money products. Cost performance metrics help you identify unexpected price increases or hidden costs and maintain a healthy profit margin for easy budgeting.

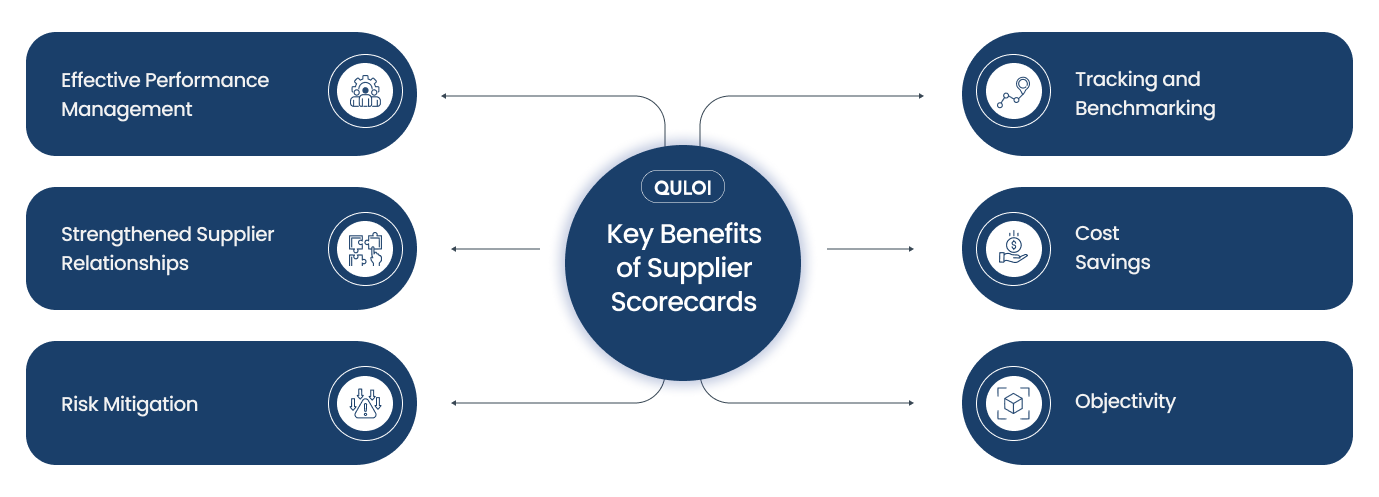

What are the Benefits of Supplier Scorecards?

Quloi’s vendor performance management scorecards are designed to optimize supplier relationships based on real-time performance data. Comprehensive supplier scorecards offer a panoramic view of supplier performance by merging quantitative metrics with qualitative assessments. The advantages of adopting these scorecards are profound:

Effective Performance Management

Supplier scorecards streamline identifying top-performing and underperforming suppliers, enabling timely corrective actions and recognition of high-performing partners. They are a valuable tool for pinpointing poor performance and recommending necessary improvements.

Enhanced Decision-Making

Vendor scorecards provide decision-makers with a wealth of quantitative and qualitative data. They facilitate well-grounded choices instead of speculative ones, leading to superior outcomes.

Risk Mitigation

Scorecards function as early warning systems, enabling organizations to detect and mitigate various risks. Whether it’s a decline in a supplier’s quality control or communication breakdowns, scorecards furnish the insights necessary for proactive risk management.

Strengthened Supplier Relationships

Comprehensive scorecards are critical in building and sustaining robust supplier relationships. They foster transparency, accountability, and open communication, setting the stage for enduring partnerships. They also foster transparency and ongoing communication between vendors and buyers, strengthening supplier relationships.

Cost Savings

Monitoring supplier performance can unveil opportunities for cost savings. For instance, if a supplier consistently makes late deliveries, this may enable negotiations for discounts or sourcing from more punctual suppliers.

Objectivity

Vendor performance scorecards facilitate data-driven, objective evaluations, reducing the risk of errors and personal biases. They enable organizations to examine supplier performance trends over time, serving as indicators of potential issues.

How to Implement Vendor Performance Management Scorecard

To embark on the journey of implementing comprehensive supplier scorecards effectively, consider these practical steps –

Define Clear Objective

Begin by articulating specific objectives for your scorecards. Determine the factors for the success of your projects. For each factor, ask questions such as, “If the supplier doesn’t perform well in this area, will it pose problems?” or “Does this impact the broader business, and is there a process to mitigate this risk?”

Customize KPIs

Tailor the scorecard to your organization’s unique needs by selecting the right KPIs encompassing quantity and quality dimensions. Consider your business goals, key suppliers, and areas ripe for improvement. Begin with a reasonable number of KPIs to ensure manageable evaluations.

Example of KPIs for Supplier Scorecards

Delivery Performance

Tracking the consistency of on-time deliveries over various periods.

Quality

Assessing the quality of supplies or raw materials each vendor provides.

Lead Time

Measuring the time between production and delivery for each product or material supplied.

Shipping Costs

Evaluating the overall cost of shipping supplies and materials from the vendor.

Assign Weights

Determine appropriate weights for each KPI based on their relative importance to your strategic goals. This weighting ensures that the most critical aspects receive attention in the evaluation process.

Determine Your Grading Scale

The grading scale on a supplier scorecard visually represents the vendor’s value to your organization. This can be a traditional letter grade scale, with “F” representing the lowest performance and “A” signifying the highest or a numerical scale. Define what each grade means and how many opportunities for improvement are provided.

Continuous Monitoring

Implement ongoing performance tracking to ensure the scorecard remains relevant and actionable. Regularly revisit your KPIs to verify their continued relevance and adapt them as needed.

Best Practices for Effective Supplier Scorecards

While implementing vendor scorecards, adhere to these best practices for optimal results –

Start Small and Simple

If you’re new to supplier scorecards, begin with a few KPIs for a select group of suppliers and progressively expand complexity as you become more comfortable with the process.

Be Transparent with Your Suppliers

Effective supplier performance management goes beyond tracking supplier quality metrics; it’s about nurturing partnerships and relationships. Therefore, be as transparent as possible with your suppliers. Ensure they understand how they are being assessed and what steps will be taken if expectations are unmet

Ensure Data Accuracy

Supplier scorecards are only as reliable as the data entered. Avoid manual data entry errors by adopting modern tools like supplier performance management systems to ensure accuracy and real-time data updates.

Seek Feedback and Collaboration

Schedule regular conversations with your suppliers to discuss performance, identify areas for improvement, and be receptive to their feedback. Effective communication is the cornerstone of successful supplier relationships.

Manage Supplier Scorecards with Quloi

Supplier performance evaluation should be collaborative, marked by transparent communication between buyers and suppliers. As supply chains evolve, embracing technology-driven solutions like Quloi is imperative to streamline the scorecard process and ensure success in the dynamic world of supplier management.

Quloi’s collaborative platform transforms order management by centralizing data, offering complete visibility into order changes and supplier performance. Every purchase order change is tracked, providing insight into shifts in lead times, pricing, response times, quantities, and delivery dates.

Are you ready to get started?

Get in touch with our experts today!

FAQs

What are the key steps of supplier evaluation?

Several steps can be taken to assess and approve potential suppliers through quantitative and qualitative assessments. Some of the key ways can be considered while evaluating supplier performance:

- Define your metrics

- Identify potential suppliers

- Communicate with suppliers

- Understanding business needs

- Defining performance indicators

- Improving supplier relationships

- Identifying risks

What does a supplier scorecard include?

A comprehensive supplier performance scorecard provides a holistic overview of a supplier’s effectiveness based on key aspects such as product quality, delivery timeliness, cost efficiency, and customer service.

How can you track supplier performance?

Supplier performance and delivery contribute significantly to your organization’s profits. Supplier evaluation cannot be solely based on cost-cutting; it is based on multiple factors. It is primarily important to define KPIs and set achievable goals to assess how your suppliers are performing. To measure their performance, you need to collect and analyze data from different sources such as purchase orders, delivery records, invoices, quality reports, surveys, audits, etc.

What are the best supplier quality metrics to track?

Supplier quality is a crucial aspect of manufacturing excellence. Some of the best supplier metrics that organizations can track are lead times, product quality, cost performance, order accuracy, communication, delivery timeliness, etc. Manufacturers who track supplier quality metrics can improve product reliability, customer service, and brand reputation. Supplier quality is important in gaining a competitive advantage in a challenging business world.

How do you maintain supplier performance?

Setting clear business goals and expectations for suppliers and monitoring their performance is critical. Monitoring and reviewing supplier interactions and performance is a key to building a strong supplier relationship. With continuous feedback, it becomes easy to identify areas for improvement and opportunities to foster partnerships. This ensures suppliers are aligned with your company’s quality and performance standards.

What are the benefits of supplier scorecard?

Supplier scorecards help maximize the supply chain’s value by tracking your suppliers’ performance against specific metrics, identifying trends, and making informed decisions about which suppliers are performing best and which need to improve. This allows you to see a balanced view of your organization.