Improve Your Lead Time with First Mile Focus

Most of us have experienced a shipping delay, lost a package, or received a damaged product, and that’s understandable, given how the shipping volume has exploded. According to a study by Pitney Bowes, the US parcel market has been increasing in volume at a 9% average rate, with revenue growth at 10% ‘17-’23 CAGR. US parcel volume growth is forecasted to shift from double-digit to single-digit and reach between 23B and 35B by 2029.

When your package arrives a little late, or not at all, have you wondered why?

Well, the “last mile” often steals the spotlight for its direct impact on customer experience. The first mile is equally crucial yet overlooked. A 2023 study by McKinsey found that about 30% of supply chain inefficiencies can be traced back to the first mile. Supply chain inefficiencies can be translated into labeling errors, packaging issues, and shipment delays. Delays don’t just add hours or days to lead times– they cause a ripple effect through the entire supply chain network. Shipping delays are usually a result of poor visibility, fragmented data, and a lack of stakeholder coordination. Shippers, third-party logistics providers, and carriers are under pressure to address first-mile inefficiencies and evolve quickly. This blog explores how businesses can unlock the untapped potential of the first mile to improve lead times and deliver optimal supply chain performance.

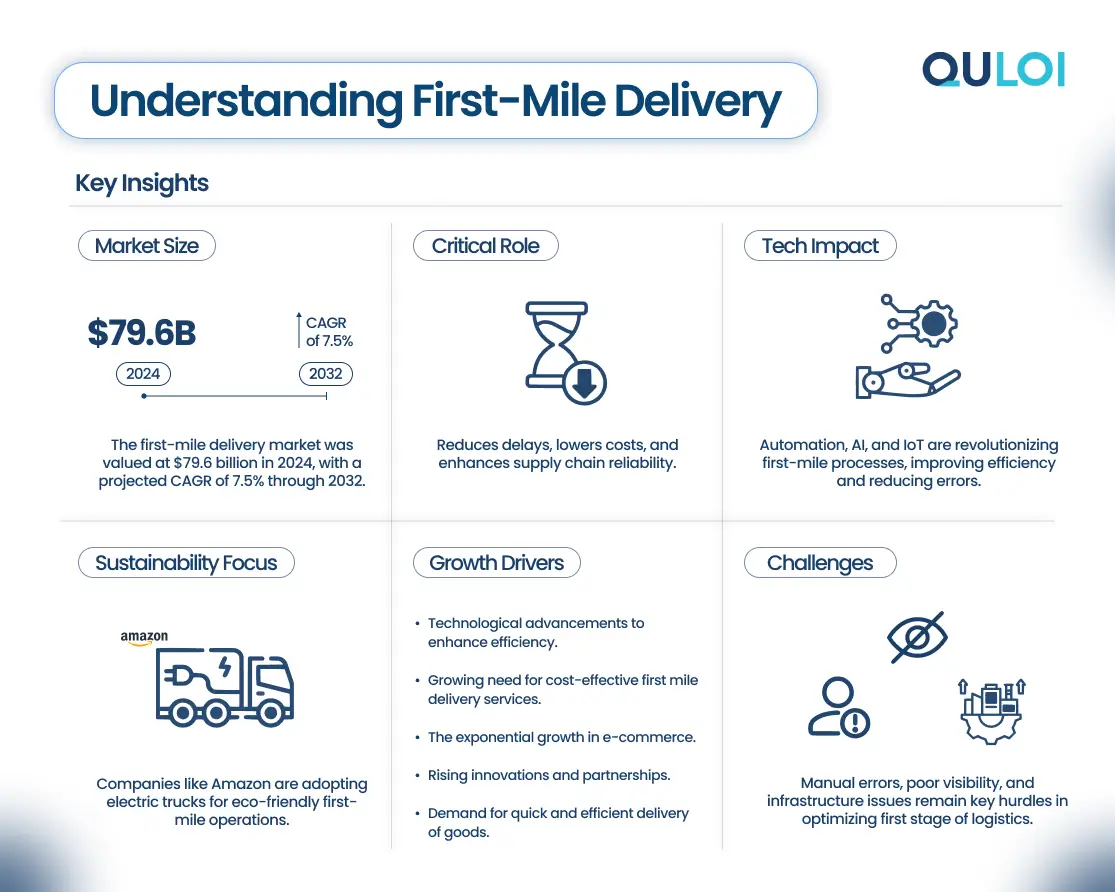

Understanding First-Mile Delivery

The first mile isn’t just the start of the supply chain journey—it’s the foundation of everything that follows, from operational efficiency to customer excellence. To quote statistics, the global express and parcels market grew by 3.8% in 2023 and is forecast to grow by 9.2% in 2024. Just count the number of delivery vehicles on your street, and you scratch the surface of the reason behind those late delivery packages. It all starts with the first mile —the often-overlooked phase of logistics, where goods move from production centers or suppliers to the next node in the supply chain. McKinsey’s study found that between 13% and 19% of logistics costs occur due to inefficient interactions and poor visibility – marking up to $95 billion in annual losses in the US alone. Further, let us understand in detail the everyday challenges of the first mile, high costs, and strategies for optimization.

Current Challenges in First-Mile Delivery

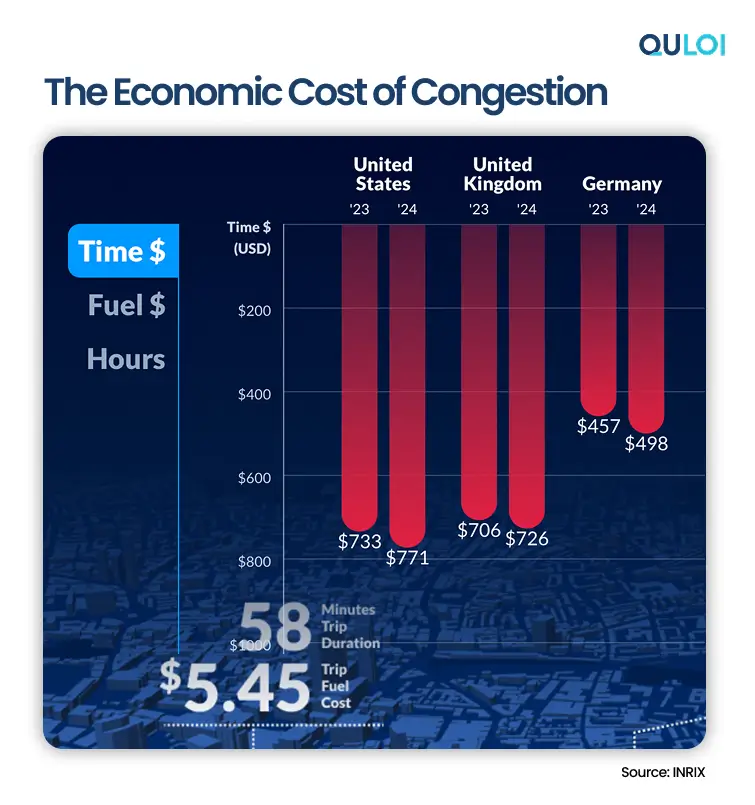

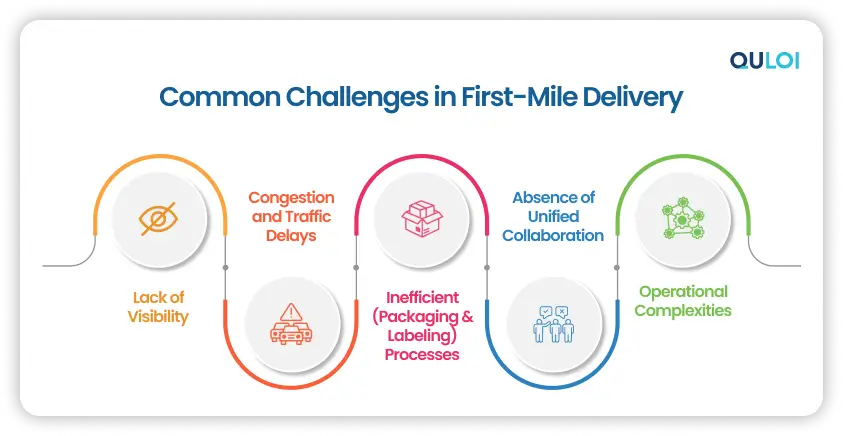

Congestion and Traffic Delays: Traffic congestion imposes significant economic costs globally by disrupting timely pickups and deliveries. Research has stated that in the U.S., drivers lose over $771 annually in lost time, totaling $74 billion nationally. The U.K. drivers lose £581 on average, amounting to a £7.8 billion national cost, while German drivers lose €470, contributing to €3.6 billion for the nation. Urban congestion costs businesses billions annually in increased fuel consumption and lost productivity.

Poor Visibility: Visibility issues in the first mile of logistics operations significantly influence the last mile, leading to improper product handling and delayed deliveries. Many businesses struggle to track their shipments timely, leading to uncertainty. For instance, if a manufacturer sends raw materials from its facility to a warehouse but cannot track their progress, it can cause production delays and inefficiencies.

Inefficient Processes: A recent study revealed that the global number of online buyers reached 2.71 billion in 2024. This whopping number of online store shoppers has boosted e-commerce growth. Of course, online purchases include returns and refunds. An NRF survey reported that an average retailer incurs $166 million in returns for every $1 billion in sales. Other costs, like two-way shipping, storage, and labor, are additional. Poor packaging and order fulfilment errors lead to costly returns and re-shipments.

Operational Complexity: The first mile can vary depending on the industry type. For example, it could involve moving products from factories to distribution centers for manufacturers. First-mile delivery may also mean transporting goods from a warehouse to local retail stores. This complexity of operations requires personalized solutions that many organizations struggle to implement effectively.

Tariffs Cause Delivery Delays – How?

If you have an upcoming package delivery deadline—even if it is just a few weeks away—you may want to consider placing your order as soon as possible. The fluctuating tariff climate in the new age makes package delivery times increasingly uncertain. US President Donald Trump has recently imposed tariffs on goods imported from Mexico, Canada, and China. These tariffs on imports from other countries are a central part of the economic strategy and aim to address issues like illegal immigration and the fentanyl crisis. It will boost US manufacturing, raise tax revenue, and grow the economy.

Here’s a breakdown of tariffs imposed by the US President:

Tariffs on Canada and Mexico: The U.S. had initially imposed a 25% additional tariff on imported goods from Canada. However, Trump recently announced a month-long tariff exemption on goods from Mexico covered by the USMCA, with a similar exemption expected for Canada. These tariffs apply to various goods, including raw materials and finished goods. Energy resources from Canada will face a reduced tariff of 10%.

Tariffs on China: Trump charged an extra 10% tariff on all goods imported from China. This is lower than the previously suggested 60% rate on Chinese goods. The tariffs apply to various Chinese goods. The de minimis exclusion previously allowed duty-free entry of goods valued under $800 in the U.S., but it was temporarily suspended and has now been reinstated.

The imposition of these tariffs has driven market uncertainty and potential price hikes for consumers. Businesses are adjusting their supply chain strategies to mitigate the negative impact of tariffs.

The High Cost of First-Mile Inefficiencies

The high cost of first-mile logistics inefficiencies is critical yet neglected, undermining the success of your supply chain. These inefficiencies have tangible financial and operational impacts across global supply chains. Let us take a closer look at data-driven insights highlighting these costs:

1. First-Mile Inefficiencies Consume Supply Chain Costs: According to a study, it is estimated that first-mile logistics consume 28-75% of total supply chain costs in the first-mile logistics due to manual processes, fragmentation, poor coordination, and limited visibility. This inefficiency leads to operational expenses and environmental aspects.

2. Lack of Automation Amplifies Costs: The first phase of logistics relies mainly on paper documentation for order management, consignment details, driver information, and scheduling. These manual processes introduce errors, delays, and inefficiencies that cascade into delayed deliveries, increased lead times, and financial repercussions.

3. Empty Miles and Trucking Costs: Empty miles caused by part-loaded trucks and inefficient delivery routes contribute to higher carbon emissions and fuel costs. In a study by the American Transportation Research Institute, trucking costs reached a record-high marginal cost of $2.27 per mile in 2023. These trucking costs were driven by empty miles during first-mile operations –straining logistics budgets and increasing overall business expenses.

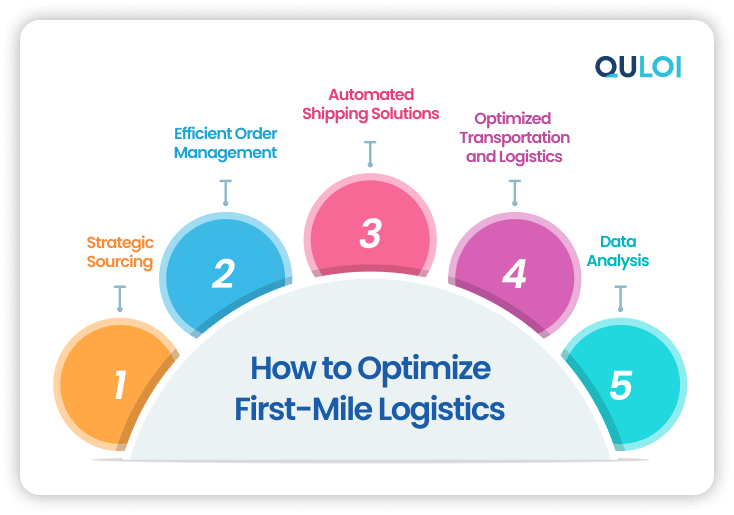

How to Optimize First-Mile Logistics?

For businesses, improving the first mile is more than saving costs—it’s a strategic imperative to stay competitive in an era of higher delivery times and rising consumer expectations. Here are a few common ways to optimize first-mile delivery:

1. Strategic Supplier Sourcing

This means finding reliable suppliers who align with your operational goals. This systematic approach to procurement ensures that raw materials or finished products arrive on time and meet quality standards. Efficient supplier management reduces delays and errors and provides the company’s competitiveness, performance, and sustainability.

Assess supplier reliability: Evaluate supplier performance based on key metrics, including lead times, quality consistency, and deadline adherence. Supplier scorecards help measure performance and make informed decisions.

Enable supplier collaboration: Treat suppliers as partners to build cooperative and mutually beneficial relationships. Hold joint planning meetings to improve communication gaps and achieve shared goals.

Implement dual sourcing: Appointing a single supplier can be risky. To ensure continuity of supply, engage two suppliers for a raw material, component, product, or service. Dual sourcing acts like a safety net if the primary supplier faces issues.

Contractual agreement: Draft contracts that outline the terms and conditions under which the supplier will deliver goods or services. It includes product or service specifics, delivery schedules, payment conditions, quality standards, etc.

2. Efficient Order Management

Order management sets a strong foundation for a smooth first-mile delivery process. Purchase orders managed systematically using an order management platform ensure speedy order fulfillment, minimize errors, and improve operational agility.

Centralized Order Management: Leverage a centralized order management system that consolidates purchase orders from multiple sales channels into a single dashboard. This improves order visibility and reduces manual errors.

Demand Forecasting: Benefit from predictive analytics to forecast future demand. Plan production and shipping schedules based on analysis of historical sales data, seasonal trends, and market conditions.

Batch Processing: Group similar orders into batches instead of handling orders individually. Place high-volume, repetitive orders simultaneously to reduce longer processing times, improve efficiency, and reduce costs.

Flexible Cut-off Times: Adjust order or shipment cut-off times based on peak and non-peak periods for greater adaptability and responsiveness. This will ensure optimal logistics performance.

3. Optimized Transportation and Logistics

One missed window in the first mile- from a manufacturer’s warehouse to a fulfillment center can cause a cascading variance in delivery time. Optimizing the first phase ensures the timely movement of goods to the next node in the supply chain. Ensure proper route planning and complete visibility to avoid late, damaged, or lost deliveries.

Partner with Local Carriers: Collaborate with local logistics providers to ensure timely and accurate pickups, leading to fast deliveries – especially in remote areas.

Route Optimization Software: Implement innovative GPS-enabled tools to identify fast and fuel-efficient routes. These platforms can help determine real-time weather forecasts and traffic conditions – reducing travel time and costs.

Consolidation Centers: Use consolidation hubs to combine multiple smaller shipments from various suppliers. This helps reduce transportation costs and ensures full truckloads, optimizing freight utilization.

Agile Fleet Models: Maintain a mix of owned and leased vehicles to adapt to changing shipment volumes and market conditions. During peak seasons, prioritize leased vehicles that can handle overflow.

4. Automated Shipping Solutions

Manual and outdated processes are prone to inefficiencies and errors. Integrating innovative solutions streamlines operations, improves visibility, and facilitates data-driven shipping decisions.

Reduced Human Error: Automated shipping solutions minimize manual data entry, resulting in highly reliable and consistent shipping. Automation ensures accurate performance of frequent tasks like data entry, label printing, and order tracking.

Real-Time Tracking: Gain visibility into delivery processes to monitor shipments timely and address issues proactively. Real-time shipment tracking helps keep customers informed about their deliveries, improving the overall experience.

Transportation Management Systems (TMS): Deploy TMS to optimize the movement of goods by automating shipment scheduling, tracking, and reporting. TMS platforms provide real-time insights into shipment status and potential bottlenecks for improved logistics efficiency.

Multi-Courier Integration: Choose the best courier for each shipment based on delivery timelines, pricing, and service quality. This allows businesses to stay agile and ensure timely deliveries, even during peak seasons or supply chain disruptions.

Barcode scanning and RFID: Equip advanced labeling systems to better manage and track your inventory. Barcodes and RFID tags offer faster scanning, and no need for line-of-sight – enabling accurate identification and minimizing losses.

5. Continuous Improvement and Data Analysis

Logistics optimization is not a one-time task to tick off your checklist. Regular analysis of logistics data helps determine any supply chain chokepoints and areas for improvement. Continuous optimization results in sustained efficiency.

Track Key Metrics: Monitor on-time delivery, transit damage rates, order accuracy, and transportation costs. Implement dashboards to visualize trends and pinpoint inefficiencies.

Consider Customer Feedback Loops: Gather customer feedback regarding delivery timelines and packaging conditions. Utilize this data to address recurring issues and make continuous product/service improvements.

Scenario Planning: Use analytics tools to simulate “what-if” scenarios and prepare for future events, such as supplier delays or natural disasters.

Employee Training: Regularly train logistics teams on best practices, industry trends, and technology innovation to maintain high standards.

Streamline First-Mile Delivery with Quloi

With consumers increasingly won and retained by on-time and accurate delivery, it is easy to see why companies are obsessed with the last mile. But, the key to a smooth and efficient logistics process is to get the first mile right. Quloi, a cloud-based purchase order management and supplier collaboration platform, transforms your first-mile operations into a strategic advantage. The centralized platform integrates seamlessly with ERP systems–ensuring data consistency and reducing manual errors. Quloi facilitates real-time communication through Slack and Teams, allowing instant messaging and actionable notifications to identify and address any errors in the first-mile delivery. The platform ensures a seamless response to requests, reduced delays, and a thorough supplier performance evaluation using supplier scorecards. Whether you want to track your orders and shipments in real time or enable seamless collaboration among stakeholders, or both (or more), Quloi will help you make every mile of your supply chain deliver excellence. The journey may begin with the first mile, but Quloi will ensure its impact resonates across every touch point in the supply chain.

Optimize your logistics with Quloi and mitigate first-mile delivery issues through end-to-end visibility, purchase order management, and supplier collaboration. Book your FREE DEMO with us and get started today!