Are You Still Using Spreadsheets for Your Supply Chain?

While the famous quote, “Insanity is doing the same thing over and over again and expecting different results,” is misattributed to Albert Einstein, it holds particularly true in the realm of supply chain management. In light of this wisdom, Quloi offers a modified version of the adage: “Insanity is using spreadsheets repeatedly to manage your supply chain operations but expecting different results.”

Spreadsheets have held a hallowed position as the go-to tools across a multitude of organizations spanning various domains, especially in the supply chain landscape. They are easy to use, low cost, versatile. They have faithfully served organizations for years, handling a multitude of tasks efficiently. so what’s all the fuss about?

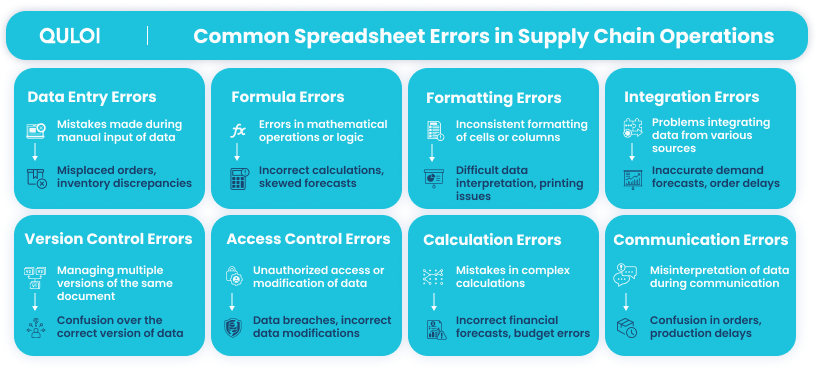

Well, the traditional approach of spreadsheets in a tech-driven and innovative business world can unwittingly create hidden dependencies on cross-departmental collaboration, hindering operational efficiency and making the supply chain complex and expensive. Every mistake within these spreadsheets—whether it’s an erroneous formula or a simple value error—can exact a heavy toll in terms of time, money, and damage to a company’s brand reputation. So if you are still using spreadsheets to manage your supply chain operations – it is imperative to reassess your approach.

Prevalence of Spreadsheets in Supply Chain Operations

Excel has been and remains a powerful tool for collecting and crunching data, but the over-reliance on it for supply chain management can pose significant risks. According to research, 67.4% of supply chain managers use Excel spreadsheets for management tasks. The idea of small and medium-sized businesses, or multi-billion-dollar conglomerates, using Excel for tracking orders, inventory management, supplier evaluation and tracking, and handling delivery data is a little worrisome.

The crux of the problem lies in the manual management of these spreadsheets, making them prone to errors. How do they handle manual processes spanning across departments or the entire organization? Who takes responsibility for checking data for error-prone entries? Consider this: the average cost of a spreadsheet error is a whopping $10,000. A single overlooked data entry or a miscalculation involving complex numbers can spell disaster for your supply chain. Moreover, transferring data from one software to another raises questions about efficiency and accuracy.

While spreadsheets offer adaptability, they may not be the most efficient tool given their limited scalability, susceptibility to errors, complex integration requirements, and significant manual effort. Regardless of the efficiency of spreadsheets, it is critical to replace them and remove existing silos for businesses. This underscores the correlation between adopting more integrated technology and fostering innovation in the supply chain.

Limitations of Using Spreadsheets in Supply Chain

Manual Data Entry

Spreadsheets require manual input for every update, causing delays in data maintenance. Integrating this data leads to duplication of efforts and increases the chance of errors. According to The Data Warehouse Institute, data entry errors in procurement, supply chain, and other areas cost businesses over $600 billion annually, affecting decision-making and efficiency.

Difficulty in Handling Large Datasets

As businesses grow, the amount of data generated increases substantially. The larger the volume of data, the more difficult it is to process manually. Spreadsheets can slow down significantly when processing massive amounts of data and increase the likelihood of human errors. Spreadsheet errors led prominent financial services firm JP Morgan to declare a loss of $6 billion.

Inefficient Data Collaboration and Sharing

Coordinating changes in a spreadsheet among multiple stakeholders is challenging, leading to versioning issues. This leads to multiple versions of the same document, leading to disputes and inconsistencies. Remote teams get limited access to spreadsheets, hindering effective collaboration and data-sharing across the business.

Poor Data Security

Spreadsheets are usually shared via email and stored on local computers or company servers. This exposes sensitive supply chain data to potential fraud and data leaks. According to research, 98% of organizations felt the negative impact of a cyber security breach in their supply chain. You cannot ensure data security and privacy to your logistics providers or suppliers if you aren’t leveraging a platform that enables additional protection for confidential data.

Difficulty in Integration

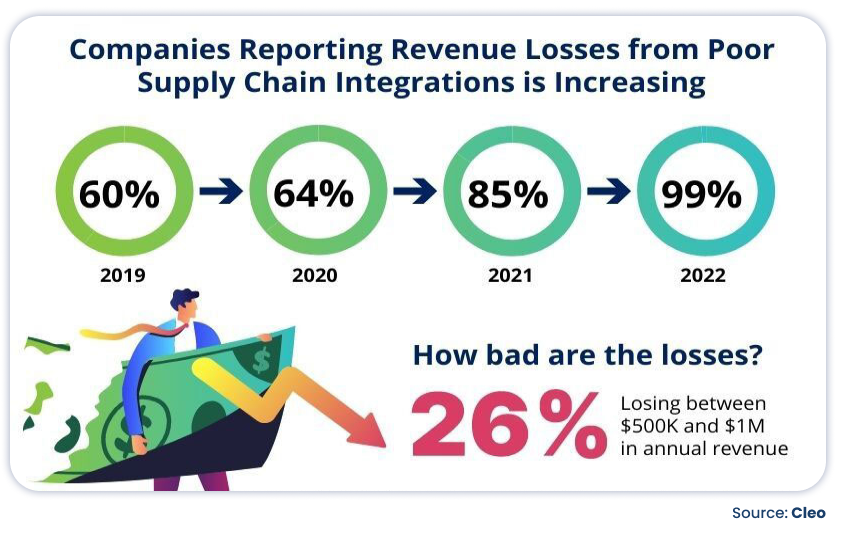

Integration challenges are expensive. A survey report showed that 99% of companies claimed losing their money due to integration issues in supply chains. Approximately, 26% of companies lose between $500,000 and $1,000,000 in revenue annually. Integrating spreadsheet data with other software used in the supply chain can be complex and may require manual data entry, resulting in operational inefficiencies and lost productivity.

Impact of Spreadsheet-Based Tracking on Your Supply Chain

Increased Operational Costs

While spreadsheets may seem cost-effective initially, they require labor-intensive data management. Whether it is errors in calculations or inadequate data management, it can lead to suboptimal inventory levels, inaccurate demand forecasts, and improper order quantities. This can result in overstocking or stockouts, driving up inventory holding costs, or causing lost sales. For example, Marks & Spencer’s failure to stock enough clothes in popular sizes during the autumn of 2019 cost them almost £5 million.

Supply Chain Disruptions

When disruptions occur within the supply chain, spreadsheets fail to provide a comprehensive view, making it challenging to identify the root causes of problems and take necessary actions. A Deloitte study highlighted the scale of manufacturers’ visibility issues. Only 13% of respondents could fully map their supply chain networks, with 72% having limited visibility beyond their ‘tier-2’ network. Also, spreadsheets do not provide adequate tools for managing regulatory issues and risks associated with supply chain disruptions. This can make the organization vulnerable to legal issues, further damaging the brand’s reputation and driving customer dissatisfaction.

Reduced Agility

Spreadsheets can hinder a supply chain’s ability to adapt quickly to changing market conditions or unexpected disruptions. They may lack the flexibility needed to adjust strategies and operations on the fly, potentially leading to missed opportunities or increased vulnerabilities.

Competitive Disadvantage

Businesses that rely heavily on spreadsheets may lag behind competitors who have adopted more advanced supply chain management technologies. This can result in lost market share and decreased competitiveness.

Strategic Limitations

Spreadsheets may limit the ability of businesses to develop and execute strategic supply chain initiatives. Lack of advanced analytics and planning capabilities can hinder long-term growth and optimization efforts.

Excel Your Supply Chain with Collaborative Visibility

However, the interdependence of suppliers, manufacturers, brands, retailers, 3PLs, logistics providers, and others simply cannot be managed effectively with Excel. These stakeholders require real-time data and a unified view of the entire ecosystem to mitigate risks. This is where collaborative visibility platforms come into play.

It’s high time to consign spreadsheets to the past and embrace Quloi’s tech-powered Supply Chain as a Service (SCaaS) platform. Discover how Quloi can help you break down operational silos, streamline processes, enhance data accuracy, and empower informed decision-making, all while maximizing opportunities.

Are you ready to get started? Get in touch with our experts today!