Mastering Supply Chain Challenges: Now and Beyond

Global supply chains are showing signs of recovery post-pandemic amid the influence of various macroeconomic factors. While supply chain disruptions persist, encouragingly, businesses are beginning to experience alleviated pressures within the logistics and transportation domains. However, we are still far away from achieving peak efficiency. As we moved closer to 2024, the familiar supply chain issues that have plagued the industry still persist. Labor and material shortages, ever-changing market demand, poor data quality, outdated technology, and limited visibility remain significant hurdles for supply chains across industries. It’s essential to proactively confront these supply chain challenges to drive sustained improvements.

What the Current Supply Chain Landscape looks like

Businesses are witnessing high demand volatility, with consumers grappling with the impact of rising inflationary pressures. A survey by The Economist Intelligence Unit (EIU) shows that disrupted supply chains have led to businesses losing 10% of annual revenue on average. The concurrence of many disruptive forces such as geopolitical conflicts, commodity price fluctuations, shipping delays, labor shortages, efficiency slowdowns, and limited visibility, will continue to test the ever-increasing complexity and interdependence of global supply chains. In response, Leaders must embrace agile methods to proactively respond to supply chain problems.

Key Supply Chain Challenges and How to Overcome Them

A combination of consumer expectations, more routes to market, international complexities, and other factors pose supply chain constraints. Let us learn what is causing supply chain issues and how we can overcome them.

Lack of Supply Chain Visibility

Visibility is a crucial factor in supply chain management. Research by Moody’s Analytics stated that over 69%of businesses believe they lack the necessary visibility over their supply chains to protect their reputation. Without a clear view of the supply chain, businesses lose their ability to react to changing customer demand, evolving market trends, unforeseen disruptions, and ultimately not delivering on their promises. This results in increased costs and revenue losses.

How to Improve Supply Chain Visibility

Enhancing supply chain visibility isn’t just a goal; it’s a crucial step toward efficiency. Start by analyzing your supply chain with process flow mapping to identify the weak points. Collaborate with business partners and empower real-time data sharing by leveraging data analytics and integrated systems to ensure seamless information flow across the supply chain, enabling quicker and more informed decision-making. Embrace digitization to automate manual supply chain tasks, from processing orders to managing inventory and planning logistics. For a comprehensive solution, consider Quloi’s cutting-edge supply chain visibility software to maximize your supply chain efficiency and transparency.

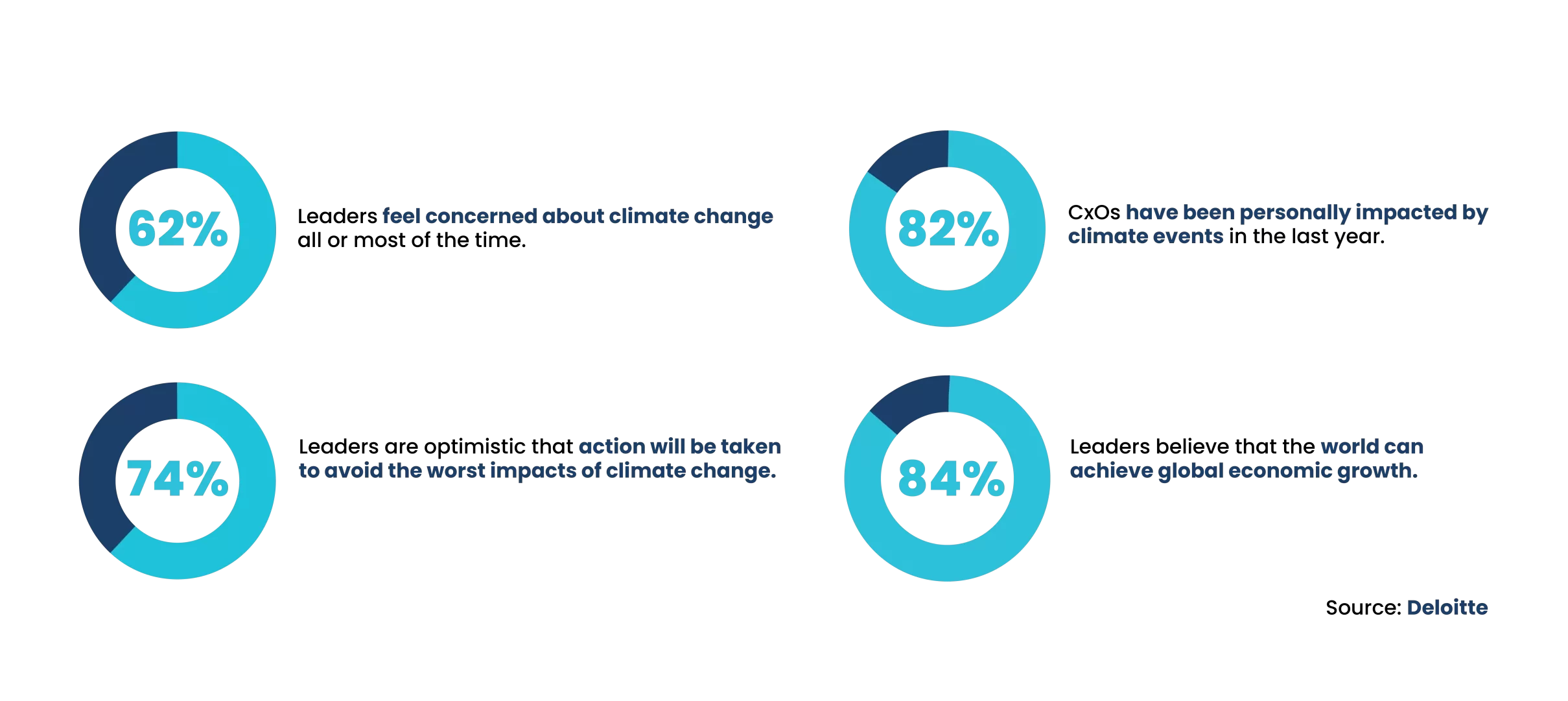

Lack of Sustainability

According to the International Energy Agency, in 2022, the rebound in passenger and cargo transport activity following the pandemic led to a 3% increase in transport CO2 emissions compared to the previous year. Transport emissions grew at an annual average rate of 1.7% from 1990 to 2022. According to IBM, about 57% of CEOs say one of the biggest challenges to sustainability efforts is to define and measure the ROI and economic benefits. The absence of robust sustainable initiatives not only hampers decision-making but also affects overall operational performance, underscoring the urgency of prioritizing sustainability measures. Further, let’s see Deloitte’s take on it.

How to Address Sustainability Issues in Supply Chain

Addressing sustainability challenges in the supply chain is a collaborative effort. Supply chain digitization offers valuable insights into operations, from transportation routes to inventory levels, asset use, and customer demand. Assess the environmental impact of your supply chain, focusing on energy consumption, waste generation, and carbon emissions. Engage suppliers, partners, and stakeholders in a shared commitment to sustainability. Leverage data analytics and digital tools for real-time monitoring and proactive decision-making.

Inconsistent Supplier Performance

Inconsistent supplier performance can significantly affect your business operations, from halting assembly lines to affecting customer satisfaction. Challenges such as poor delivery schedule adherence, subpar quality standards, communication gaps and lack of flexibility and outdated technology can lead to increased lead times, production delays, and even stockouts, directly affecting your ability to meet customer demand. Underperforming suppliers not only harm operational efficiency but also risk eroding customer trust and loyalty, potentially resulting in lost sales and a damaged brand reputation.

How to Address Supplier Performance Issues

- Leverage Supplier Scorecard to measure supplier performance against critical aspects such as document centralization, on-time delivery, lead time accuracy, and other crucial KPIs to drive continuous improvement.

- Implement Supplier Development Framework to foster collaboration and streamline sourcing.

- Invest in suppliers’ growth through training and development opportunities to bolster their quality skills and capabilities.

- Recognize and reward suppliers as an incentive for exemplary performance. For eg: reward your suppliers with increased orders, longer contracts, preferential terms, or referrals.

Labor Shortages in Supply Chain

According to research by Korn Ferry, businesses across the globe could be dealing with a labor shortage of 85.2 million skilled workers by 2030. The potential impact on revenues is staggering, forecasted to reach approximately $8.45 trillion, equivalent to the combined GDPs of Japan and Germany. Due to the acute labor crunch, supply chains experience a range of difficulties including delayed shipments, cash flow constraints, inferior product quality, and customer service issues. These supply chain challenges put pressure on the entire ecosystem.

How to Combat Labor Shortages

- Conduct regular training sessions to help employees stay engaged, informed, and confident in their roles.

- Embrace technology to automate repetitive tasks, streamline processes, and enhance operational efficiency

- Prioritize attracting and retaining top talent by offering competitive compensation packages, a positive work environment, and growth opportunities

- Strengthen relationships with suppliers and partners by collaborating on demand forecasting, inventory management, and resource allocation

Demand Volatility in Supply Chain

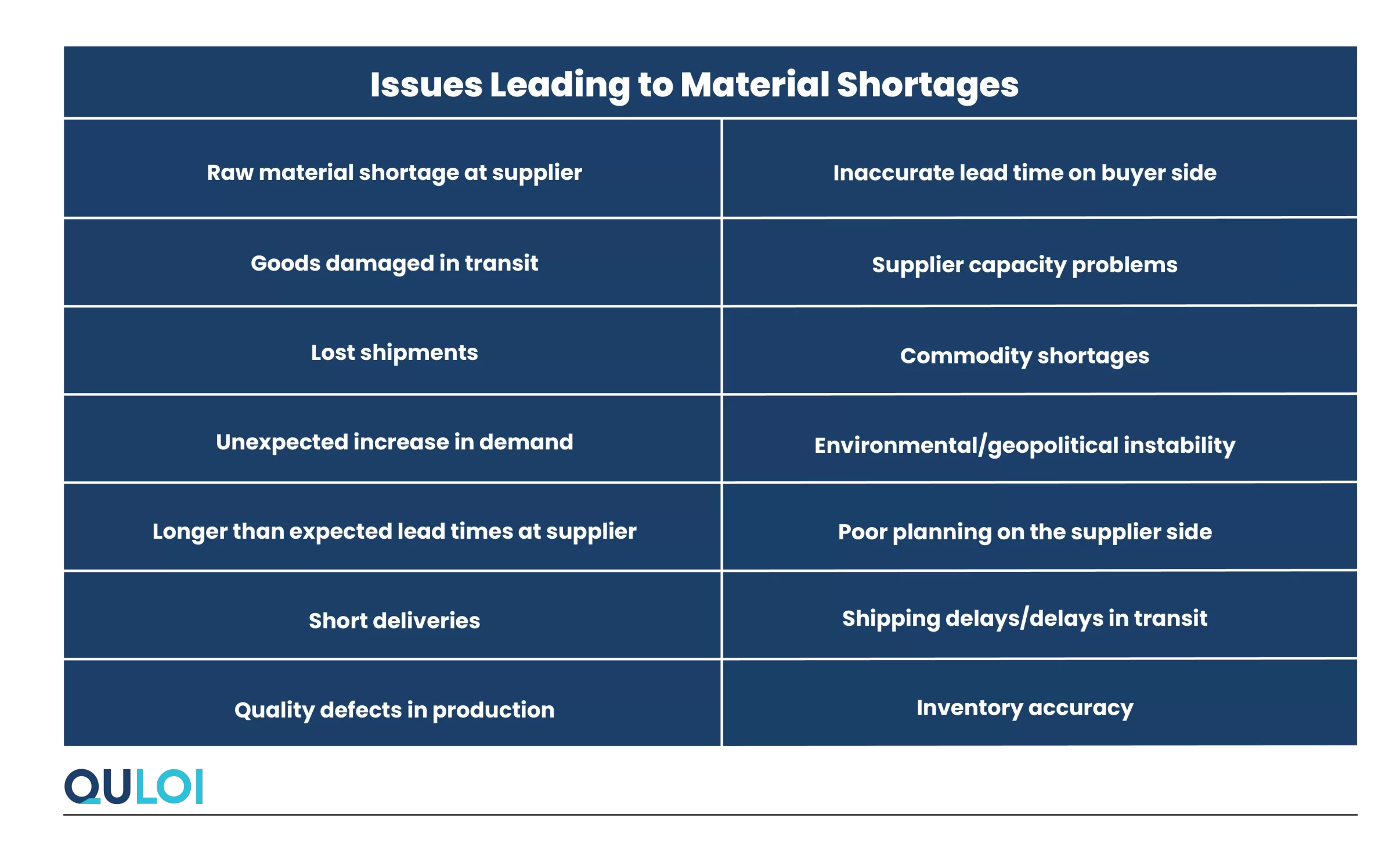

Demand volatility, often driven by unpredictable market shifts, is a critical factor in supply chain dynamics and is closely linked with material shortages. When demand experiences sudden fluctuations, as seen with the recent surge in semiconductor demand, it can outpace supply capabilities. As demand surges, suppliers may struggle to keep up, further straining the availability of crucial materials. The consequences of these shortages are felt across industries, from electronics to manufacturing and beyond. Other elements such as rapidly changing consumer preferences, market trends, economic shifts, and unforeseen events (like global pandemics) contribute to this volatility that can lead to stockouts, production delays, and operational disruptions

How to Mitigate Demand Volatility

- Encourage supplier collaboration to establish accurate lead times and enhance efficiency overall efficiency, enabling a smoother flow of materials and products.

- Optimize inventory to identify potential shortages in advance.

- Incorporate accurate demand forecasting to better anticipate fluctuations, allowing supply chains to adjust proactively.

- Keeping a close eye on market trends ensures timely adaptation to shifting customer preferences, industry developments, and emerging opportunities.

- Optimize Inventory Management to identify potential shortages in advance, facilitating proactive measures to maintain uninterrupted operations.

Escalating Transportation and Freight Costs

The freight forwarding market in 2023 experienced significant improvements, however, other factors like trade tensions, geopolitical uncertainties, and shifts in consumer demand impact supply chains. A report published by Siam Shipping featured that the volume of goods transported by ocean freight experienced a sharp 5.7% decline in 2023 compared to the previous year. This decline underscores the need for organizations to reevaluate their approaches and adjust to the changing market dynamics.

How to Handle Rising Transportation and Freight Costs

- Provide your drivers with well-optimized routes.

- Look for suppliers based near your ship-to points

- Consolidate shipments where feasible to maximize capacity utilization and reduce per-unit transportation costs

- Collaborate with suppliers to enhance supply chain visibility, synchronize demand forecasting, and implement shared transportation strategies

- Incorporate sustainable practices such as adopting greener fuel options that not only benefit the environment but also lead to cost savings in the long run

Technology Hangover

With outdated technology, supply chain organizations run the risk of poor data management capabilities to leverage all information to make business decisions. Inaccurate or poor data can be financially devastating, causing potential revenue losses of up to 20%. Research by McKinsey shows that 73% of companies use spreadsheets for supply chain planning. Outdated technology and manual processes can result in data loss and restrict employees from achieving higher productivity. Decreased efficiencies will pull companies away from maximizing revenue and gaining a competitive advantage.

How Advanced Technology can Optimize Supply Chain Issues

- Real-time data-driven decision making

- Increased end-to-end visibility

- Better inventory management

- Increased collaboration between supply chain partners

Overcome Your Supply Chain Challenges With Quloi

Quloi, an innovative-first mile, collaborative supply chain digital platform responds directly to the needs of manufacturers, suppliers, and freight forwarders. Through its optimized supply chain platform, Quloi provides context-specific, action-based first-mile collaboration, thereby eliminating tedious manual data entry and replacing it with the automatic collection of relevant data. Take control of your production process when you enable effective collaboration, document centralization, and automated processes. Get in touch with our experts to schedule a demo and learn how Quloi can help you overcome supply chain challenges and achieve desired business outcomes.