Maximizing Efficiency Through Supply Chain Collaboration

While supply chain disruptions continue to become a norm, the margin of error within supply chain operations increases. Neglecting workflow inefficiencies in your supply chain can cost your business dollars. But thanks to collaborative supply chains, it’s never been easier for organizations to avoid supply chain challenges. Supply chain collaboration is ideal for organizations to achieve increased visibility, accurate lead times, cost-effectiveness, and overall operations efficiency.

What is Supply Chain Collaboration?

Supply Chain Collaboration means multiple organizations working in a coordinated manner to improve operational efficiency and achieve common supply chain goals. It means establishing real-time shared visibility with supply chain partners to meet demand and ensure on-time, in-full delivery efficiently. A collaborative supply chain encourages cross-functional teams to drive innovation, producing more market-responsive business /offerings. Collaboration covers every aspect of the supply chain, from purchase order processes and demand forecasting to quality management and capacity planning.

Types of Supply Chain Collaboration

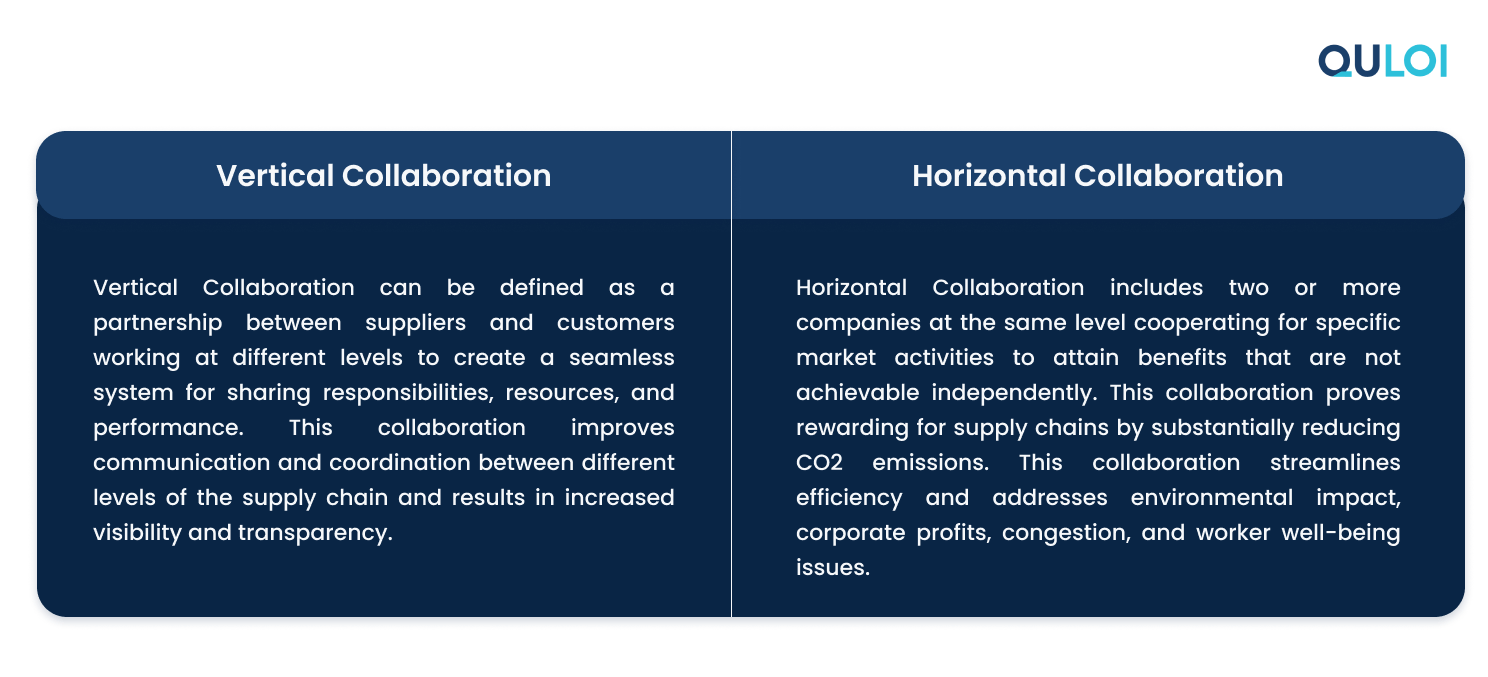

Collaboration in the supply chain becomes critical as manufacturers enter new markets with newer product portfolios and evolving business practices. And no wonder organizations collaborating effectively across the supply chain enjoy responsive and cost-effective supply chains. Collaboration is divided into two main categories:

Importance of Collaboration in Supply Chain

With supply chains spanning multiple regions and involving numerous stakeholders, including suppliers, manufacturers, distributors, retailers, and service providers, there must be integrated systems to generate the results. However, that is not the case. Supply chains remain fragmented and vulnerable to various risks, with different departments operating on different systems, KPIs, and multiple versions of the truth.

Data from one department isn’t necessarily shared across other departments. For instance, if the manufacturer and its crucial supplier do not communicate effectively, production cycles might fluctuate. These inefficiencies can result in delayed deliveries and increased costs – disrupting the entire supply chain. Through a supply chain collaboration platform, stakeholders can share data from a unified platform and jointly explore new processes and business models. A survey featured that working collaboratively with suppliers is a crucial focus: 53% rated this among their most significant opportunities for improving supply chain management. This can help companies navigate inefficiencies and orchestrate their supply chain to ensure a seamless flow of information and goods.

Key Stakeholders in Supply Chain Collaboration

Supply Chain Collaboration involves multiple stakeholders working together on a single platform to enable information sharing and optimize the flow of goods and services.

Benefits of Supply Chain Collaboration

Increased Visibility

Collaboration enables seamless data sharing and information across the supply chain network. Real-time data hosts various benefits, such as improving visibility and transparency, maximizing efficiency and productivity, boosting customer satisfaction, and improving responsiveness. With complete visibility into the supply chain, organizations can anticipate disruptions and adjust their strategies accordingly. Discover how digitalization enhances supply chain visibility and drives operational excellence.

Improved Supplier Relationship

Collaboration fosters trust and mutual understanding among supply chain partners by creating cross-functional teams, using technology to facilitate smooth communication. This becomes invaluable during times of crisis. Suppliers prioritize organizations with whom they have built positive relationships, ensuring a continuous supply of goods despite uncertainty.

Reduced Lead Times

A Deloitte study reported that 40% of supply chain organizations identified late delivery as their biggest problem. Any delays in the supply chain result in miscommunication and, ultimately, extended lead times. Collaboration among supply chain partners leads to innovation and technology integration. By automating order processes, productivity and responsiveness to customer demands increase – minimizing the impact of delays. This efficiency results in quicker response times during disruptions.

Enhanced Agility

According to a survey, 40% of organizations find real-time responsiveness a top barrier to supply chain success, and 34% find it challenging to meet customer demands on time. Collaborative supply chains allow organizations to respond to shifting dynamics in the industry with agility and innovation. When supply chain stakeholders communicate effectively and work together, they can reduce lead times, minimize the risk of disruptions, and achieve streamlined supply chain performance.

Risk Sharing and Mitigation

Collaborative efforts allow supply chain partners to share risks and together mitigate disruptions. By collaborating closely, partners can identify vulnerabilities and take necessary actions to reduce the impact of unexpected events. This helps build a safety net against potential threats, thus improving overall supply chain efficiency.

How Quloi’s Supply Chain Collaboration Platform Helps Achieve Efficiency

Unify Operations and Enhance Collaboration

Quloi’s supply chain collaboration platform is designed to break down silos and foster seamless teamwork among all stakeholders. By providing a collaborative workspace, it empowers everyone involved in the supply chain to work together efficiently, minimizing manual data entry and significantly boosting productivity.

Centralize Data for Easy Access

Quloi offers a centralized information dashboard with easy navigation and individual supplier snapshots, complete with insights and exception alerts. This consolidated view equips manufacturers with critical information, including key milestones and alerts, accessible with a single click, simplifying decision-making processes and enhancing overall visibility.

Effective Supplier Performance

Quloi’s performance scorecards assess supplier performance against document centralization, on-time delivery, lead time accuracy, and other crucial KPIs. This empowers organizations to track supplier performance, identify areas for improvement and set meaningful benchmarks.

Lead Time Accuracy

Quloi enables you to monitor the movement of goods and shipments in real time and provides timely updates on production status and inventory levels. This enables buyers and suppliers to adjust their plans accordingly, leading to on-time delivery performance.

The Path Forward is Clear

Stay competitive with Quloi’s supply chain collaboration platform and take your supply chain operations to the next level. Book a free demo today to learn how our unified platform empowers stakeholders to communicate and collaborate with maximum efficiency.