BullWhip Effect in Supply Chain: Causes and Solutions

You’re standing in the supermarket aisle, looking at an empty shelf where your favorite brand of juice, yogurt, or cookies is usually stocked. What you see could result from the bullwhip effect.

Distorted information across the supply chain can lead to excessive inventory and storage costs, poor customer service, inadequate transport infrastructure, and ineffective production scheduling – resulting in operational inefficiencies and lost revenues. How do little customer changes lead to a wave of order exaggeration? What actions do companies take to mitigate them? Do companies consider integration for seamless data sharing?

Different stakeholders in the supply chain have limited control over the whole process, but their actions influence decision-making. As these players respond to market dynamics and demand variations, they reverberate throughout supply chain operations. One of these is the bullwhip effect.

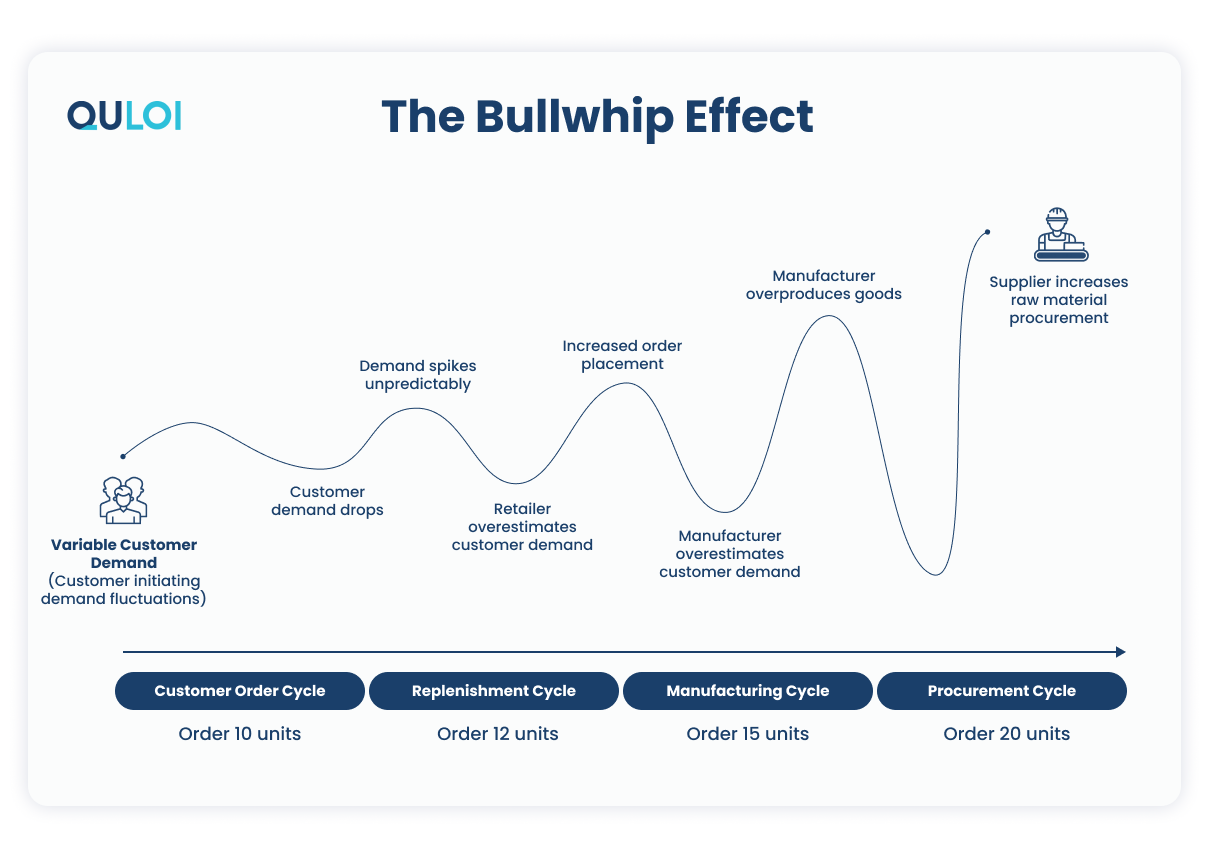

What is Bullwhip Effect in Supply Chain?

Bullwhip or Whiplash Effect refers to a chain reaction due to the continuous variations in customer demand, making critical disruptive adjustments at the manufacturer’s end. It leads to either extra or less buying of supplies. It results in inventory fluctuations and missed production schedules, leading to excess inventory or stockouts. The famous American investor, Michael Burry, made headlines in June of 2022 when he warned investors about the bullwhip effect for big-box retailers and others.

Examples of Bullwhip Effect

1. Toilet Paper Shortage during COVID-19

Panic buying of toilet paper during the pandemic pushed stores to increase their orders and keep their shelves stocked. Manufacturers, likewise, increased production to align with the excessive increase in customer demand. Such distortion of demand and increased volatility significantly impacted the retailers, marketers, and manufacturers.

2. Ice Cream Sales

Imagine a retailer selling ice cream. On an unusually hot day, they sell 230 cups instead of 200 cups (usually). Mistaking this as a trend, the retailer orders ingredients for 250 cups, causing unnecessary fluctuations.

Causes of Bullwhip Effect in Supply Chain

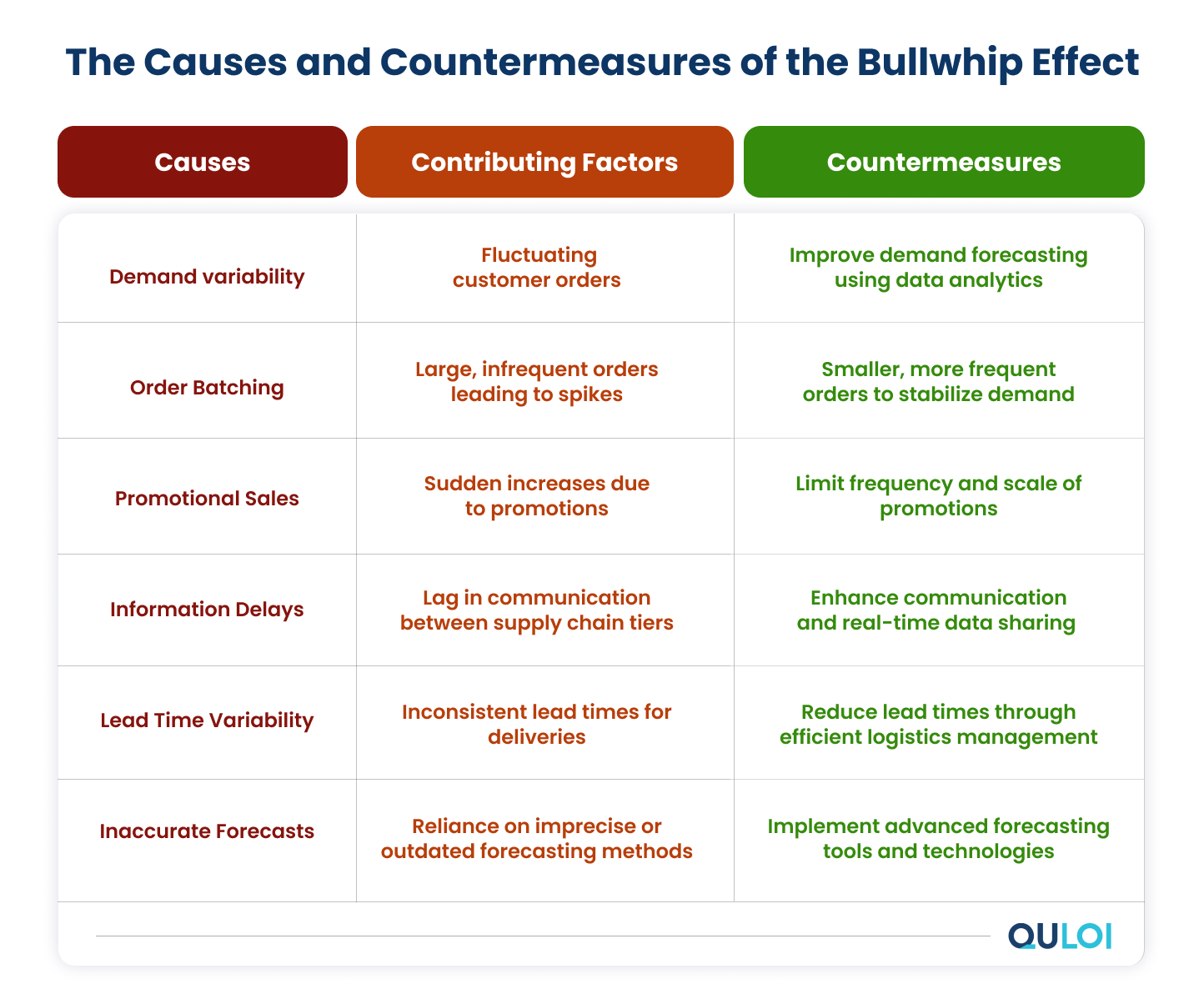

Order Batching

This is a common practice where companies consolidate different orders and place them in batches rather than in a continuous flow. For example, a fashion retailer may order bulk T-shirts to reduce frequent ordering costs. However, this could lead to excess inventory that might pile up for T-shirts with declining demand. And, if those T-shirts suddenly become popular at multiple stores, but the order batching schedule is infrequent, there could be stockout until the next batch arrives.

Price Fluctuations and Promotions

Price fluctuations and promotional discounts can often disturb regular buying patterns. Buyers want to make the most out of discounts offered during a specific period, leading to inaccurate demand forecasting and overproduction of goods. The rapid fluctuation in goods or their prices makes it difficult for suppliers to forecast future prices, resulting in increased inventory levels accurately and an amplified bullwhip effect.

Inaccurate Demand Forecasting

Suppliers, retailers, and distributors forecast demand based on their sales data, but these predictions can prove wrong due to unforeseen market shifts, seasonal changes, or sudden fluctuations in consumer demand. Even minor errors can accumulate and lead to overestimated demand and increased inventory.

Lack of Supply Chain Collaboration

When there’s inadequate communication among supply chain entities, information about actual demand takes time to reach upstream partners. Delays in communication or errors in information amplify the bullwhip effect in supply chain management. As a result, stakeholders may undercompensate or overcompensate while adjusting their orders, creating a cumulative distortion.

Lead Time Issues

Longer lead times in the supply chain mean lost revenue. When there are delays in receiving products due to extended lead times, retailers may place large safety stock orders to ensure their shelves don’t remain empty. In order to place larger orders to compensate for the perceived or buffer against potential shortages, companies end up over-ordering and excessive inventory buildup – amplifying the bullwhip effect.

Consumer Pressure

Manufacturers and distributors receive orders from retailers, and consumer demand strongly influences retailers. Consumers may exhibit stockpiling behavior to benefit from product promotions or discounts, leading retailers to adjust their orders to suppliers accordingly. Fluctuating orders from retailers can challenge manufacturers in production schedules, resource allocation, and inventory control.

Operational Costs

Manufacturers often prefer order batching to minimize operating costs. While this approach may help them save on ordering costs, it also leads to irregular larger orders that might not align with actual demand. Consequently, manufacturers and distributors have to bear the brunt of managing production schedules, inventory, and logistics operations based on information from retailers or consumers. This information could be distorted due to cost-driven practices – ultimately contributing to the bullwhip effect.

How the Bullwhip Effect Impacts Your Supply Chain?

Inventory Instability

As each supply chain stakeholder overreacts to demand fluctuations by under-ordering or over-ordering, it leads to stockouts or excessive inventory. This mismatch between demand and supply can chip away at profit in the long run. Goods that are not on the shelf or risk becoming obsolete and undesirable can result in costly waste.

Increased Storage Costs

An increase in the production of goods is directly related to a rise in inventory. The longer inventory goes unsellable, the more likely excess inventory will clog up warehouses. This can be expensive, as you have to pay for the physical storage space and other costs associated with its storage. The cost remains usually high as the stock no longer yields returns caused by fallen demand.

Increased Labor Costs

The more inventory manufacturers have, the larger the workforce they need to manage an overloaded warehouse. There are costs associated with handling, sorting, and selling the overstocked inventory you have on hand. On the contrary, manufacturers could see increased workforce demands if they face inventory shortages since their employees may need to work harder to meet customer demands.

Strained Supplier Relationships

The bullwhip effect can damage relationships among supply chain partners. Continuous variations in demand can create a cycle of instability and mistrust, as suppliers and manufacturers might perceive these variations as unreliable forecasts or sudden changes in delivery commitment.

Minimize Bullwhip Effect in Supply Chains

Improve Order Planning

Use historical data, statistical models, and data analytics to forecast demand more precisely. Communicate & collaborate closely with retailers and suppliers to exchange real-time customer demand, inventory levels, and sales information. You can implement demand-driven replenishment to avoid under-ordering or over-ordering.

Order in Batches

Place orders in large quantities but less frequent batches to stabilize demand fluctuations. Strike the right balance when placing large orders to avoid excess inventory and storage costs. Limit Your Promotions, Limit the frequency and scale of promotions, discounts, and sales events to maintain stable demand patterns. Monitor the impact of promotions and other marketing tactics on demand patterns and adjust accordingly.

Leverage Forecast Tools

Utilize advanced forecasting tools and technologies to analyze historical data-and seasonality trends and predict demand accurately. Practice collaborative forecasting with partners in the supply chain to align production and inventory levels more effectively.

Reduce Lead Times

Shorten lead times between order placement and delivery to avoid the need for excessive inventory buildup or rushed production runs. Discover third-party logistics (3PL) to expedite transportation and minimize transit times.

How Does Quloi Help You Navigate the Bullwhip Effect?

Leverage Collaboration

By establishing robust communication channels and facilitating real-time information sharing, Quloi helps eliminate information delays contributing to the bullwhip effect. A collaborative environment ensures all stakeholders access accurate data to understand demand and maintain inventory levels.

Integration Capabilities

Quloi, a cloud-driven platform, seamlessly integrates with the most common ERP touchpoints. This integration ensures a smooth flow of data and information across different supply chain partners, minimizing forecasting and order processing errors.

Order Optimization and Visibility

Our platform automates manual order processing and reduces the potential for order batching. Additionally, with end-to-end visibility across the supply chain, you can gain real-time insights into inventory levels, order statuses, and demand patterns.

Efficient Supplier Management

The Quloi platform nurtures stronger partnerships by enabling a unified platform for better communication, collaboration, and performance tracking. As a result, it simplifies supplier management from onboarding to ongoing performance assessment.

FAQ’s

What is the bullwhip effect in the supply chain?

What causes the bullwhip effect in the supply chain?

- Fluctuating customer orders and uncertain market conditions

- Distorted demand information due to poor communication

- Large, irregular order placements by retailers

- Sudden increases in demand due to promotions or sales

- Inconsistent lead times for deliveries

- Reliance on outdated forecasting methods

How to reduce bullwhip effect?

1. Opt for smaller, more frequent orders.

2. Collaborate to share real-time data and minimize information delays.

3. Limit promotions to prevent sudden spikes in demand.

Can you eliminate the bullwhip effect?

It can be difficult to eliminate the bullwhip effect entirely; however, it can be mitigated by taking proactive measures such as accurate demand forecasting, real-time data sharing among supply chain partners, and reducing order delays.