Supplier Collaboration is the Key to Future Proof Your Business

The global pandemic exposed a harsh reality: The fragility of modern, disconnected supply chains, revealing an inconvenient truth: no organization thrives in isolation. Business success hinges on collaboration – not just with customers but with the backbone of your operations: your suppliers. Imagine: Your next big launch jeopardized by a missing screw. Sounds stressful?

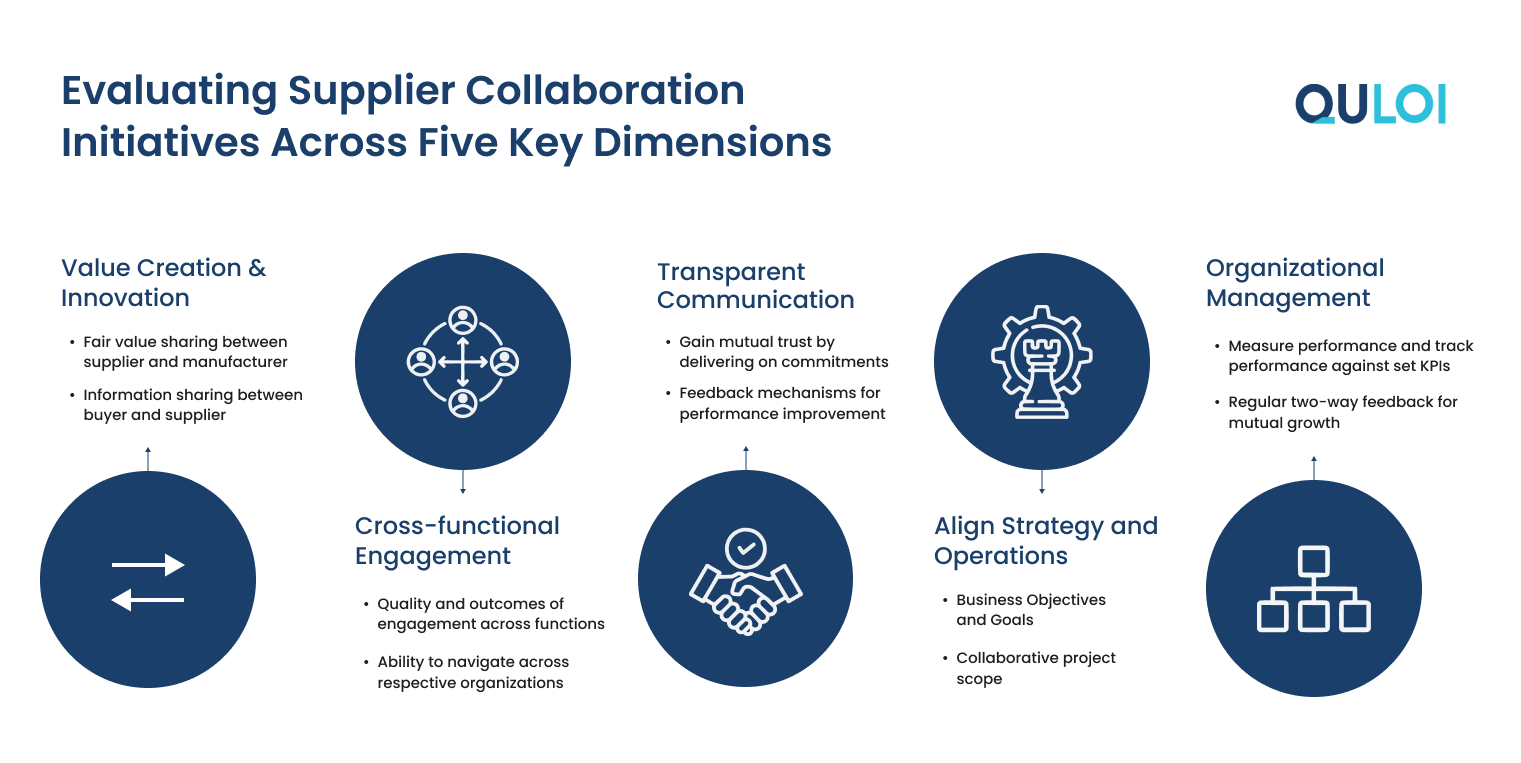

For manufacturers and distributors, complex supplier relationships are part and parcel of their routine. Yet, the evolving business landscape demands more. Customers crave transparency, agility, and customized solutions, while intense competition and global disruptions threaten stability. This is where supplier collaboration becomes a transformative lever to boost efficiency, optimize costs, and unlock innovation.

Importance of Supplier Collaboration

Outdated supplier collaboration methods, like endless email chains and siloed data, are costing manufacturers and distributors dearly. A recent IDC study revealed that 68% of organizations still rely on emails for procurement and supply chain communication. Telephone (44%), supplier/customer portals (38%), and EDI (26%) are the other used methods that are used. Most organizations struggle to collaborate efficiently with suppliers. It’s often one-way and inefficient. Consider the countless e-mails and follow-ups. It takes this long to find and buy from suppliers. It is high time for organizations to focus their efforts on supplier management practices and attain operational excellence.

Effective supplier collaboration aims to streamline operations through optimized lead times and improved customer demand with minimal expenditure on back orders and inventory.

Let’s understand the value of collaboration through an example:

Imagine a leading electric car manufacturer struggling with unpredictable battery deliveries, impacting production schedules and customer satisfaction. They gained real-time visibility into production capacity, lead times, and potential disruptions by implementing a collaborative planning platform with their key battery supplier. This enabled them to share detailed production schedules and anticipate demand forecasts with the supplier, who, in turn, provided early warnings of potential issues and adjusted production accordingly. As a result, lead times were reduced by 20%, production delays minimized, and customer satisfaction significantly improved.

Benefits of Supplier Collaboration

The absence of collaboration in an organization affects operational efficiency. A 2023 survey revealed that 52% of engineers spend at least six hours per week on supply chain-related tasks, including sourcing vendors, providing and requesting quotes, and ordering parts. This indicates a 73% increase from 2022. On the contrary, 63% of manufacturers prioritizing supply chain collaboration reported on-time delivery rates of over 95%.

Effective supplier collaboration builds strategic partnerships. By working closely with your suppliers through shared platforms, data transparency, and joint planning, you unlock a world of benefits:

Reduced lead times

Predict and respond to demand fluctuations together, ensuring you have the right materials when needed, and minimizing inventory costs.

Enhanced agility

Proactive communication and shared insights allow you to adapt quickly to market changes and disruptions, staying ahead of the curve.

Improved Supply Chain Visibility

Modern supplier collaboration platforms unite buyers and suppliers through a consolidated view of purchase orders and order statuses. With collaborative networks, both parties have a common understanding of price, quantity, and timelines.

Fostered Innovation

A comprehensive business-to-business collaboration platform that connects stakeholders, systems, and processes across multiple enterprises allows organizations to share data, exchange new ideas, and manage workflows easily. By collaborating on process optimization initiatives, supply chain partners foster a culture of innovation, leading to continuous enhancements in supply chain performance.

Strengthened Relationships

Long-term collaboration fosters trust, transparency, and cooperation among stakeholders. Developing strong relationships encourages open communication to align goals and share expertise. Regular meetings, shared platforms, and standardized reporting formats are common ways to strengthen relationships.

Risk Management

Supplier issues, transportation delays, natural disasters, or supply chain disruptions can have severe consequences. Effective communication allows stakeholders to manage risks by proactively sharing information and implementing mitigation strategies. Communicating potential disruptions and working together to develop contingency plans helps minimize the impact of unforeseen events, ensuring uninterrupted business continuity.

Cost Savings

Establishing relationships with key suppliers leads to cost savings through various avenues. By sharing insights and best practices, businesses can identify opportunities for process optimization and cost efficiencies. Additionally, collaborative relationships with suppliers may result in negotiation, pricing, or discounts, further contributing to cost savings.

Your suppliers aren’t just vendors; they’re an extension of your team. Investing in strong, collaborative relationships creates a win-win situation, driving mutual success and ensuring a smooth flow from raw materials to satisfied customers.

Steps to Improve Supplier Collaboration

Choosing the Right Fit

Don’t just go for the lowest price. Select suppliers who align with your values, goals, and long-term vision. Analyze performance on key metrics like quality, responsiveness, and innovation potential.

Enabling Supply Chain Visibility

The ability to track products at any point along the supply chain gives buyers a holistic view across all suppliers. Digitization enables a fully integrated supply chain ecosystem, enabling visibility, more effective collaboration, and maximized work efficiency.

Use Data and Analytics

Track and analyze KPIs like on-time delivery, quality defects, and lead times. Identify areas for improvement and collaborate with suppliers to address them proactively. Remember, not all KPIs are equal; prioritize based on your specific needs. For instance, improving delivery times may be more critical than cutting cost per unit, as it can significantly impact the entire supply chain.

Foster Open Communication

Break down silos and establish clear communication channels. Utilize collaboration platforms, hold regular meetings, and encourage open dialogue to address concerns and share updates proactively. Avoid misunderstandings and ensure everyone is on the same page

Implement Collaborative Technologies

Utilize cloud-based platforms, data analytics tools, and automated workflows to streamline collaboration and data exchange. Modern technology is your key to seamless coordination and efficiency gains.

Maximize Your Supplier Collaboration with Quloi

Supplier Collaboration is no longer a nice-to-have for any organization but a must-have. Businesses working closely with suppliers can communicate effectively, streamline processes, and make informed decisions that lead to shorter lead times. A study by Deloitte revealed that over half of the companies are looking to meet supply chain challenges by diversifying suppliers and supply routes and increasing collaboration with suppliers. The survey also reported that 40% of CFOs want to use digital planning tools to keep supply chains moving under tough economic and geopolitical conditions. As supply chain professionals contend with challenges, Quloi’s cloud-driven supply chain management platform ensures:

- Automated order processing, minimizing the need for manual data entry and human errors.

- Improved supplier performance against set targets.

- Seamless collaboration among suppliers, manufacturers, and distributors by sharing key information, fostering stronger partnerships.

- Real-time visibility into order status and logistics, enabling proactive decision-making.

- Seamless integration with most common ERP touchpoints to enable smooth data flow.

- Unified platform to access, exchange, and use important information to optimize lead times.

Building strong supplier collaboration is an ongoing process. Create a win-win environment that fosters mutual success, reduces risk, and drives long-term growth for your organization and your partner.

Frequently Asked Questions

What is supplier collaboration?

Supplier collaboration is a strategic approach to supplier management. It allows buyers and suppliers to work closely to align systems, share information, and make joint decisions. Collaboration between supply chain partners is believed to create significant value and help supply chains become more resilient.

What are the types of supply chain collaboration?

There are two main types of supply chain collaboration

Vertical Collaboration: When two or more organizations from different levels in the supply chain share their responsibilities, resources, and performance.

Horizontal Collaboration: It enables organizations at the same level to allow ease of work and cooperation toward achieving a common goal.

What is an example of a collaborative relationship in a supply chain?

Let us understand collaboration through this example:

An electronics manufacturer relies on various component suppliers to provide display screens and microchips. The manufacturer’s success is influenced by the timely delivery of high-quality components from its suppliers. To foster collaboration, both parties engage in the following practices:

- Joint planning

- Shared risk management

- Performance measurement and feedback

- Process improvement and innovation

What are the advantages of collaborative relationships between buyer and supplier?

Here are the key advantages of collaborative relationships:

- Improved communication

- Better decision-making

- Streamlined processes

- Enhanced trust and transparency

- Increased innovation

- Efficient problem-solving

- Increased innovation

- Cost savings

How can supplier collaboration be improved?

You can learn to improve supplier collaboration by following these practices:

- Enhance communication channels

- Enable visibility and transparency

- Understand contractual obligations

- Encourage continuous feedback

- Leverage technology for mutual benefit