Supply Chain Audit: A Comprehensive Step-by-Step Guide

Supply chains become more interconnected as businesses continue to source raw materials and products from suppliers globally. Problems that used to remain isolated earlier now have far-reaching effects on your supply chains. At the same time, product lifecycles and customer expectations continue to shift. Today’s customers expect businesses to deliver faster, better, and cheaper. This challenges traditional notions of ‘acceptable supply chain risks.’ This requires building resilient supply chains by managing known risks and preparing for the unknowns.

But how do you make your supply chain risk-ready for risks you cannot anticipate?

Businesses can only improve what they see, whether fixing a problem or preparing for a potential risk. However, supply chain audits provide comprehensive visibility that companies need to identify and fix blindspots and unspecified risks. Conducting a supply chain audit is an effective way to examine the overall health of your supply chain and address inefficiencies.

This blog is your complete guide to learning the importance of a supply chain audit, why you should conduct auditing, and what best practices you can implement to achieve operational excellence and strengthen supply chain resilience.

What is a Supply Chain Audit?

The importance of conducting in-depth supply chain audits cannot be overstated, particularly when global disruptions, underperforming suppliers, and vendor miscommunication impact supply chain performance. These audits provide actionable insights that help organizations identify vulnerabilities and improve operational performance. Failure to obtain accurate information—whether due to oversight or intentional misrepresentation—can have serious consequences. It can damage brand trust, lead to product recalls, incur high operational costs, expose companies to legal risks and potential fines, and hinder timely decision-making.

Let’s understand the importance of supply chain audit through Nike

You cannot improve what you cannot see. Unfortunately, the athletic-wear manufacturer Nike experienced it firsthand. Nike faced significant issues in its supply chain due to a lack of visibility and auditing. In 2022, the American sportswear brand reported a record 44% increase in inventory levels, reaching $9.7 billion. These numbers are attributed to an accumulation of seasonal products that did not sell as intended. The excess inventory resulted in misalignment with consumer demand. This is just the tip of the iceberg. Every function in every stage of the supply chain, from procurement and production to warehousing, inventory, order fulfillment, and last-mile delivery, needs supply chain auditing.

To quote statistics, 79% of organizations with high-performing supply chains achieve revenue growth significantly above their industry average. The key reason behind this is leveraging supply chain digitization and conducting regular supply chain audits – an imperative that helps businesses enhance their supply chain performance.

Supply chain audits help organizations ensure that operations evolve alongside dynamic market trends, changes in global trade, limited resources, and other factors that affect supply chains. End-to-end visibility in the supply chain and a clear understanding of business needs are critical in improving relationships among business stakeholders. Organizations can optimize their supply chain operations through regular auditing and open communication for improved performance and resilience. An effective auditing program drives business success by ensuring risk mitigation, cost optimization, supplier performance evaluation, compliance assurance, and continuous improvement.

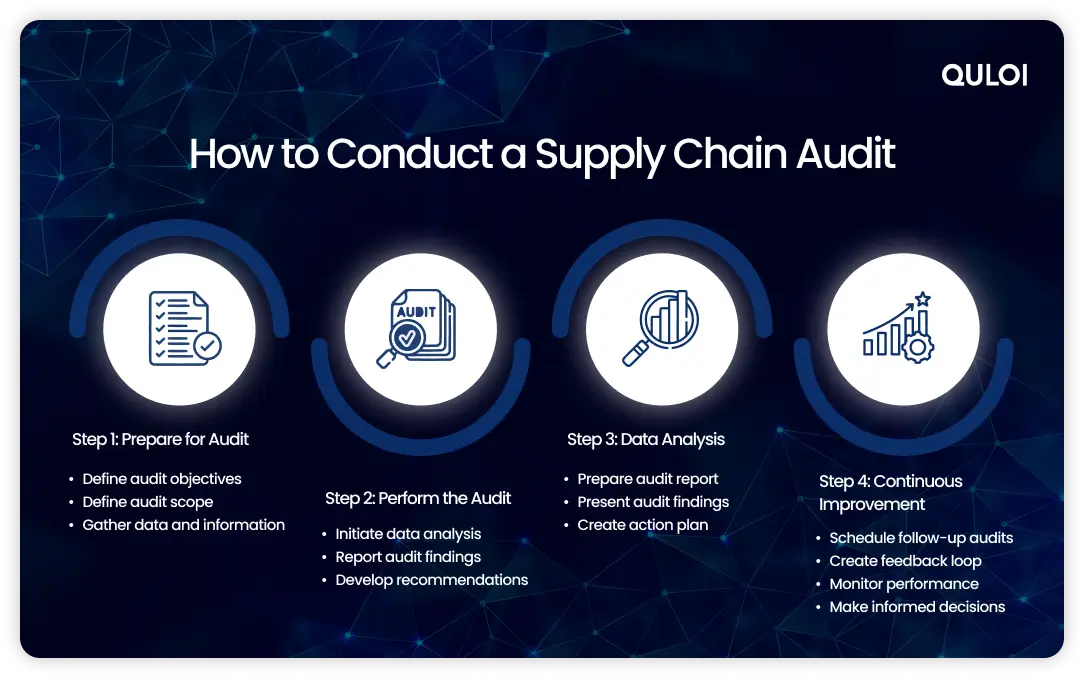

How to Conduct a Supply Chain Audit?

A good supply chain audit process ensures businesses understand their strengths, weaknesses, blindspots, opportunities, and threats. Conducting a supply chain audit may seem overwhelming, with various evaluation areas. Let’s get started with a standard step-by-step guide:

- Prepare for audit: Define clear objectives and goals aligning with your organization’s values. This could include assessing regulation compliance, evaluating supplier performance, optimizing inventory, mitigating risks, or identifying cost-saving opportunities. By gathering relevant data and information like contracts, interviews, and document reviews, companies can save time and effort and determine where businesses lack supply chain visibility and transparency. For example, Procter & Gamble (P&G) focuses on sustainability in its supply chain audits. The multinational consumer goods brand aims to reach zero greenhouse gas emissions across its supply chain by 2040. The company evaluates its suppliers’ adherence to environmental standards as part of its sustainability goals.

2. Perform the audit: Conduct supplier assessments using a multi-faceted approach, including stakeholder interviews, surveys, online assessments, and on-site inspections. This approach helps you validate the information gathered during data collection. For example, an American beverage company, Coca-Cola, prides itself on strong quality, food safety, and regulatory compliance. The company conducts regular onsite assessments as part of its supplier audits to ensure safety standards for the products it produces and distributes. The continued testing and auditing program has helped Coca-Cola avoid potential disruptions related to supplier quality issues.

3. Analyze the Data: Leverage analytical techniques like gap or SWOT analysis to ensure the audit is as comprehensive as possible. Ensure you use all data collected from apps, sensors, and IoT devices to identify strengths and weaknesses and prioritize areas for improvement effectively. Data analysis during an audit is helpful in predictive maintenance, warehousing, quality control, logistics and transportation optimization, demand management, supplier relationship management, and risk management. Based on your analysis, document your audit findings clearly to identify risks and improvement opportunities. It helps companies significantly reduce operational costs and promotes optimal supply chain performance.

4. Improve Continuously: With insights in hand, it’s time to prioritize implementing a robust improvement plan. Action plans should focus on improving operational processes, addressing compliance issues, achieving sustainability goals, strengthening supplier relationships, and more. Communicate the action plan to relevant stakeholders to implement and monitor progress over time. For example, following its audits, Unilever took preventive measures to address adverse impacts directly linked to supplier’s operations, products, or business processes. Regular supply chain audits help companies ensure that every link in their supply chain operates efficiently and ultimately drives profitability.

How Quloi Helps?

Achieving continuous supply chain improvement can be challenging, especially for organizations that rely on global sourcing, manufacturing, and delivery operations.

Quloi, the cutting-edge supplier management platform, enhances supply chain audits’ efficiency by centralizing all relevant data. This allows stakeholders to access information quickly without sifting through multiple sources. This provides real-time notifications on critical events, enabling proactive actions to minimize errors. The platform facilitates supplier scorecards to help businesses identify underperforming suppliers and take corrective actions timely. By enabling centralized workspaces, Quloi encourages transparent stakeholder communication to ensure smooth audit processes. Also, Quloi streamlines document management by organizing necessary documents in one place and providing accurate data flow.

Contact our experts to discover how Quloi helps you with smooth auditing by enabling supply chain visibility, centralized workspaces, digitized document management, and more.