How Digitalization Enhances Supply Chain Visibility

Supply chain visibility has long been recognized as a crucial component in the fast-paced global marketplace, with its absence leading to significant challenges and repercussions for both businesses and consumers. The key to addressing these challenges lies in understanding what supply chain visibility entails and how digitalization can transform every aspect of supply chain operations, from planning to logistics. At the heart of this transformation lies the critical role of supply chain visibility software. As a catalyst for operational excellence, supply chain visibility software enables agile decision-making, increased efficiency, and superior customer satisfaction.

What is Supply Chain Visibility?

Supply chain visibility (SCV) refers to the ability to track and monitor goods and/or products as they move through the supply chain. It enables organizations to collect, analyze, and share reliable data and information across the entire supply chain network, including suppliers, manufacturers, distributors, retailers, and customers.

With effective inventory management, limited disruptions, and proactive risk mitigation in place, SCV allows manufacturers to exercise greater control over operational expenses and enhance customer service levels. This improves the supply chain’s speed, accuracy, agility, and granularity while reducing operational costs. Additionally, a transparent and interconnected supply chain fosters stakeholder collaboration for process optimization and improved efficiency.

Significance of Supply Chain Visibility

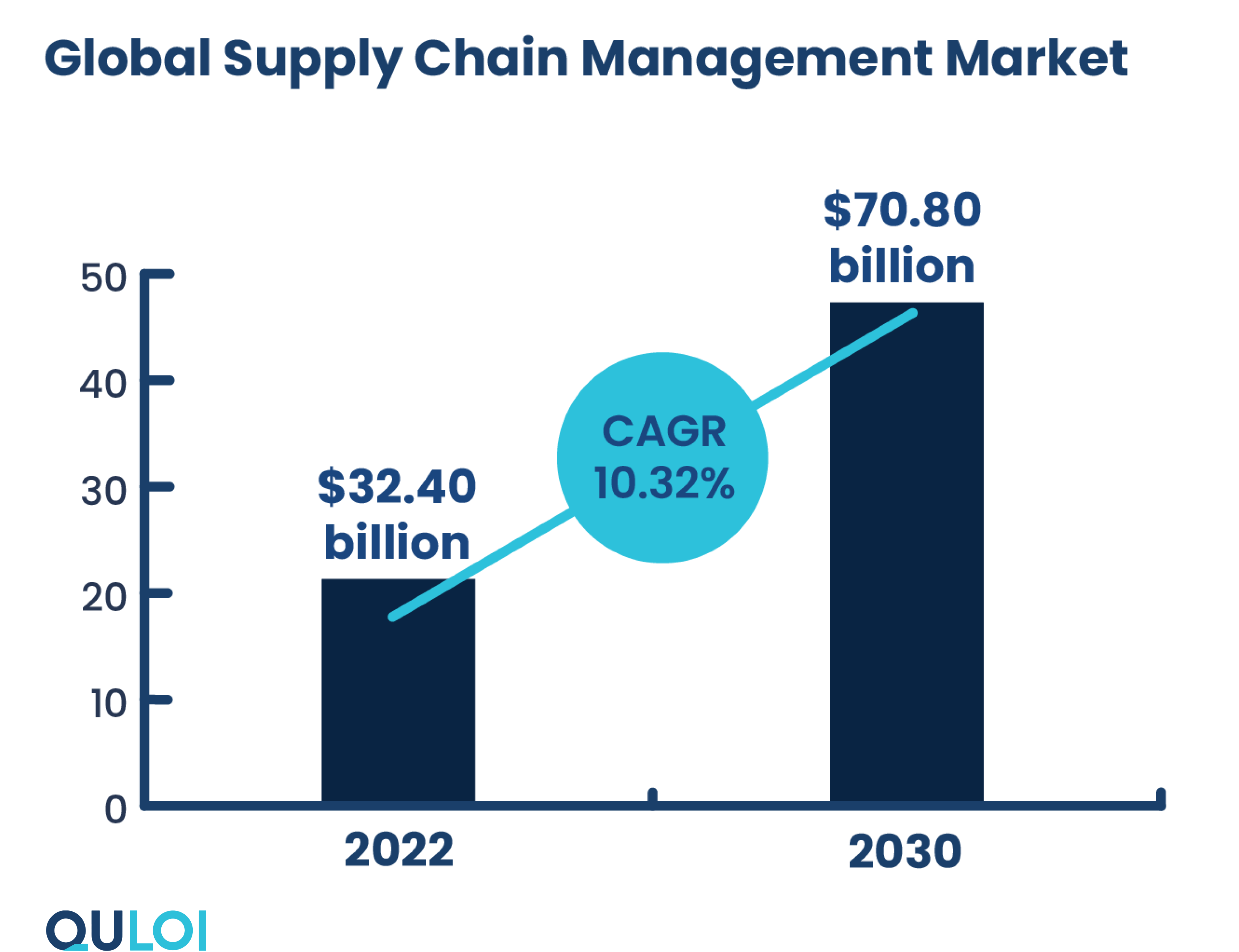

According to Verified Market Research, the Global Supply Chain Management (SCM) market was valued at $32.40 Billion at the end of 2022 and is expected to reach $70.80 Billion by 2030, growing at a CAGR of 10.32%.

It is evident that effective supply chain management is a key driver of business success, however, it is disconcerting to note that just 13% of firms have supply chain visibility as reported by a Deloitte study. The report further found that up to 22% of firms have no visibility beyond their immediate suppliers.

Supply Chain directly impacts customer satisfaction, the lifeblood of any business. With end-to-end visibility, companies can enhance compliance, optimize operations, forecast demand accurately, and gain a competitive advantage. This means promptly addressing customer inquiries, maintaining regulatory standards, measuring key performance indicators, making informed decisions, and leveraging insights for collaboration and innovation. Supply chain visibility is no longer an option but a necessity for organizations aiming to thrive in the fast-paced and ever-evolving market.

Key Challenges to Achieve Supply Chain Visibility

Data Silos: Information about the supply chain is often scattered across different systems and departments, leading to data silos and a lack of integrated visibility. Data silos prevent the flow of relevant information, hamper data collation, hinder operational performance, and make it difficult to leverage data analytics to gain a bigger picture.

Data Integration: The diverse systems and stakeholders involved in the supply chain often use different data standards, formats, or systems, resulting in data silos and fragmented information. This lack of integration hinders the ability to obtain a comprehensive and real-time view of the entire supply chain.

Lack of Real-Time Data: Limited access to real-time data can often lead to difficulty in tracking supply chain activities. Traditional supply chain models find batch processing highly reliable, resulting in delayed and outdated information. Lacking one version of the truth can directly impact efficiency, profitability, and an organization’s ability to effectively optimize operations as a whole.

Fragmented Data and Processes: A lot of organizations have manual processes, outdated technologies, fragmented IT systems, and disconnected workflows. This fragmentation can hinder visibility efforts and reduce the opportunities for data sharing and collaboration, as data may reside in different systems or be inaccessible to key stakeholders.

Complex Supplier Networks: Global supply chains often involve multiple suppliers, subcontractors, and logistics providers. As the supply chain network expands, the complexity increases, making it quite difficult to track and trace goods or identify bottlenecks or inefficiencies.

Lack of Visibility and Transparency: Limited visibility into multi-tier supply chains can pose several challenges like inefficient inventory management, poor demand forecasting, increased lead times, inability to respond to disruptions, quality control issues, etc. All of this can hurt a company’s margins and jeopardize its competitive edge.

Benefits of Supply Chain Visibility

Proactive risk management: A Blue Ridge study reported that supply chain disruptions could cause adverse losses in terms of finances (62%), logistics (54%), and reputation (54%). With end-to-end supply chain visibility, organizations can proactively identify and mitigate risks before they occur. For instance, they can track potential disruptions caused by political instability, natural disasters, cyber threats, or supplier issues and develop contingency plans to minimize their negative impacts and maintain continuity in their operations.

Improved operational efficiency: Supply chain visibility enables organizations to identify and eliminate inefficiencies and bottlenecks in their operational processes. Procter & Gamble (P&G) significantly improved their supply chain by implementing supply chain visibility solutions. With real-time data on inventory levels and production schedules, P&G optimized its operations, cut down inventory holding costs, and increased its inventory turnover.

Compliance and Sustainability: With improved supply chain visibility, organizations can monitor and verify product origin, quality, and safety, ensuring compliance with regulations and ethical standards. Moreover, end-to-end supply chain visibility allows companies to track and manage their environmental footprint, promote sustainable practices and reduce waste throughout the supply chain processes.

Seamless Data Integration: By implementing advanced data integration technologies, like application programming interfaces (APIs) and electronic data interchange (EDI), it becomes easier for manufacturers to facilitate seamless data exchange between different systems. They can achieve data interoperability with the effective use of standardized data formats like XML or JSON.

Effective demand forecasting and planning: With real-time supply chain visibility, organizations better understand demand patterns and market fluctuations. Organizations can improve their demand forecasting accuracy by analyzing data on sales, inventory levels, and ongoing market trends. Walmart has been investing massively in supply chain transformation, and recent studies affirm that the company leveraged AI and ML to track and trace products from farm to shelf. This initiative helped Walmart optimize inventory levels, identify and recall contaminated food products faster, and reduce the risk to customers – resulting in cost savings and improved profitability.

Enhanced customer service: Companies implementing visibility technologies can provide accurate and reliable information to customers regarding the status of their orders. Real-time tracking information helps manage customer expectations, builds trust, reduces order inquiries, and improves overall customer satisfaction.

Digitalization and Its Potential to Enhance Supply Chain Visibility

As challenges emerge and the supply chain becomes more complex, it becomes difficult for companies to gain end-to-end supply chain visibility and position themselves at the forefront of the competition. Digitalization enables a fully integrated and highly efficient supply chain ecosystem that is fully transparent to all partners involved in the supply chain process.

Track-and-trace Systems: According to McKinsey, the supply chain is responsible for more than 80% of a company’s environmental impact. Digital tracing technology like RFID (Radio Frequency Identification), barcode scanning, or GPS (Global Positioning System) offers quicker route optimization and consequently reduces their ecological footprint. With real-time information about the location, movement, and status of products, companies can easily monitor their inventory and ensure on-time delivery.

Blockchain technology: According to a market research study published by Contrive Datum Insights, the Blockchain for Supply Chain Market is projected to reach $16.67 Billion by 2030. Supply chain organizations can utilize blockchain technology to enhance visibility through a shared, tamper-proof system of records accessible to all authorized parties. IoT sensors: IoT (Internet of Things) sensors can be integrated into products, packaging, or transportation vehicles to capture data on multiple aspects like temperature, humidity, or shock. This data helps organizations monitor product quality, detect issues during transportation, and ensure regulatory compliance. Amazon, for example, uses IoT-enabled robots for warehouse operations management through QR code scanning on packages.

Collaborative platforms: Cloud-based platforms enable stakeholders to collaborate and share information in the supply chain. With an effective collaborative system, suppliers, manufacturers, distributors, and retailers can exchange data, track shipments, and coordinate activities while ensuring better visibility and synchronization across the supply chain.

Supply chain analytics: By implementing data from various sources such as ERP, warehouse management systems, and transportation management systems, organizations can uncover valuable insights from their operations. Integrating supply chain analytics into operations, makes it easier to identify trends, optimize routes, streamline processes, and make data-powered decisions.

How Quloi Can Help You Enhance Supply Chain Visibility

Quloi offers a comprehensive suite of advanced software and tools, real-time tracking technologies, and data-sharing partnerships designed to enhance supply chain visibility. Their advanced supply chain visibility software consolidates data from various sources, such as suppliers, manufacturers, distributors, and retailers, into a centralized platform. By embracing digitalization as explained in this whitepaper, Quloi helps organizations transcend the limitations of operational inefficiencies, outdated technology, manual processes, and fragmented data. Real-time tracking, seamless data integration, advanced analytics, and effective collaboration pave the way for a more resilient, agile, and efficient supply chain. Through data-sharing partnerships and collaborative platforms, Quloi’s supply chain visibility software connects suppliers, manufacturers, distributors, and retailers on a unified platform. This transparency eliminates information silos and fosters better coordination and decision-making.

Are you struggling to measure your supply chain performance and capture its full potential?

Let Quloi help you navigate the complexities of the supply chain landscape and unlock its true potential!

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.