Best Practices to Reduce Backorders and Improve Supply Chain Efficiency

Have you ever encountered a production bottleneck caused by an unexpected stockout at a key supplier? Backorders, a typical consequence of demand exceeding supply, can significantly disrupt your carefully planned manufacturing schedules. This leads to costly delays and potentially jeopardizes on-time deliveries to your clients. Effective inventory management and clear communication across the supply chain are crucial for mitigating backorders and ensuring a smooth flow of goods.

What Does a Backorder Mean?

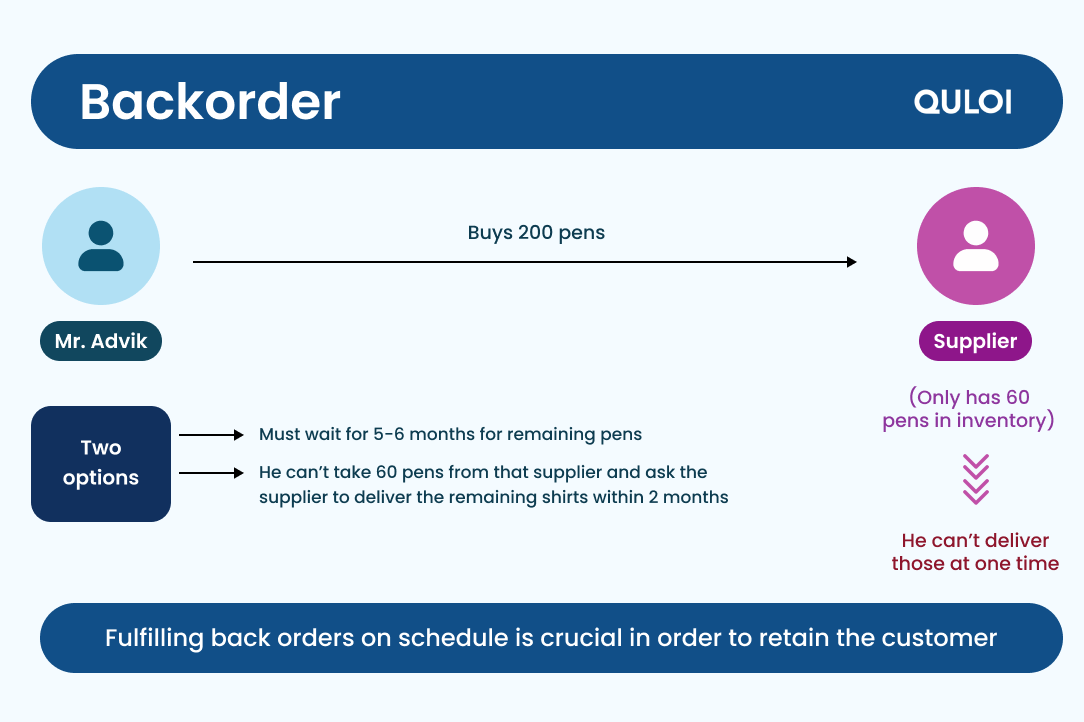

A backorder occurs when an order can’t be fulfilled at purchase because the seller needs more stock. Backorders, a common supply chain challenge, can disrupt production schedules, lead to order cancellations and revenue loss, and strain buyer-supplier relationships.

Key Reasons for Backorders in a Supply Chain?

Forecasting Errors: Inaccurate forecasting can result in the risk of you operating under low safety stock, which could result in stockouts that end up as backorders when demand exceeds available inventory. If an organization produces lesser units of a product based on inaccurate forecasting, it may end up with limited inventory that can lead to stockouts. On the other hand if you produce too many units it may lead to excess inventory that ties up storage space and capital.

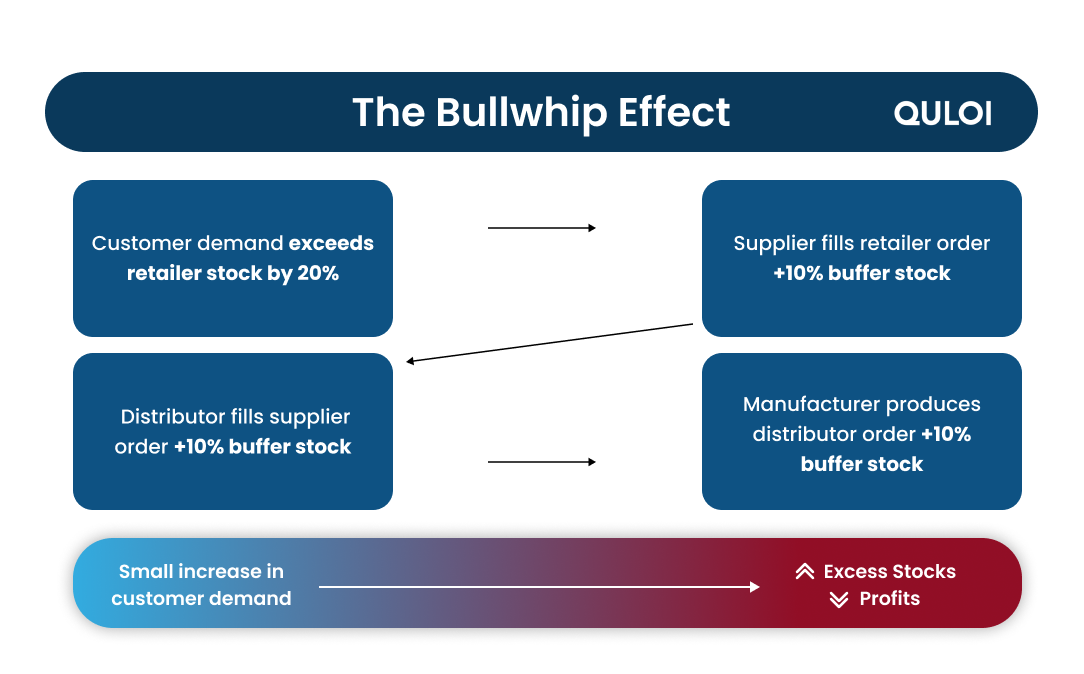

Demand Unpredictability: When demand for certain products becomes unpredictable, it is difficult to determine the number of items your customers require. For instance, sudden surge in demand due to holidays, evolving market trends, seasonal variations or a product going viral might affect your ability to meet the growing demand. These unforeseen fluctuations create a “bullwhip effect” throughout the supply chain, ultimately leading to backorders and higher costs.

n also result in backorders.

Lead Time Variability: Inefficient routing or warehouse congestion can slow shipping or transportation. Sometimes, equipment breakdowns, supplier delays, or shortages of skilled labor in manufacturing can delay production and push back the delivery date. This mismatch between planned arrival dates and reality creates backorders when stock doesn’t arrive at the destination on time.

Poor Communication: Poor communication with suppliers can cause further delays in restocking inventory and ensuring backorder fulfillment. Suppliers may not prioritize allocating sufficient resources if they are unaware of the urgency, resulting in increased lead times and frustrated customers.

Supply Chain Disruptions: Natural disasters, transportation challenges, or unexpected events like strikes can cause delays or interruptions in the flow of goods causing delays and and backorders. For instance, if a factory that produces a particular washing machine component is flooded and has to shut down temporarily, the manufacturer won’t get an adequate supply to assemble their washing machines. As a result, customers who ordered those washing machines might have to wait longer than expected.

Customer Demand Variability: Variations in customer demand patterns, order quantities, order sizes, and delivery preferences can pose challenges for inventory management and fulfillment. Last-minute order changes or cancellations disrupt inventory planning and increase backorders.

Backorders and Keeping Customers Happy

In today’s cutthroat business environment, striking the right balance between inventory levels and customer needs feels like walking a tightrope. Ideally, you would like to have all your products readily available to to ship the moment a customer clicks “buy.” However, unexpected demand surges or supplier hiccups can throw a wrench in those plans.

Importance of Backorders

Backorders act as a safety net, allowing you to capture sales even when an item is temporarily out of stock. While not a perfect solution, backorders offer some key advantages:

Customer Retention: Backordering ensures that businesses don’t lose customers to their rivals. It is useful when demand exceeds supply within a specific period. Research states that, on average, a backorder delay can decrease customer orders by 2.1% in the subsequent year. Among customers who experience a shipping delay beyond 10 days, businesses experience a 6.1% reduction in orders the subsequent year and a 4.6% loss in cumulative orders over four years. As a result, businesses lose 25 million dollars in profit every year.

Maintaining Customer Satisfaction: By accepting backorders, you avoid the risk of losing a customer who wants a specific product. This can be especially important for businesses selling unique or highly sought-after items.

Revenue Retention: Instead of turning away a potential sale, a backorder allows you to secure a customer’s commitment and capture revenue later when the item becomes available.

Reduced Costs: Holding massive amounts of inventory increases the carrying cost and may also result in deterioration for environmentally sensitive products. Backordering helps organizations minimize their warehousing costs. Companies can benefit from this as they can cut inventory holding costs. Moreover, small businesses can use this to their advantage by stocking only a few items customers want

While they can help maintain customer satisfaction and revenue in the short term, it’s important to remember that backorders are not a silver bullet. Just like a slight dip in OTIF performance (on-Time and in-full deliveries) can have serious consequences, poorly managed backorders can lead to a cascade of negative impacts on your business.

Impact of Backorders

Declining Sales: When customers find out the product they want is temporarily out of stock and on backorder, they might want to buy from elsewhere. Waiting for a back ordered item can be frustrating and disappointing for customers, mainly when they expect to receive it within a particular time frame. This negative experience means the business loses out on a potential sale. Research shows a single bad experience can lead a customer to share their story with up to 15 people.

Inventory Management Challenges: Companies may need to rush production or buy additional inventory from suppliers to ensure backorder fulfillment. This can lead to excess inventory in warehouses, increasing carrying costs. On the flip side, backorders can also result in stockouts. This can happen when companies fail to forecast demand accurately or there are delays in inventory replenishment.

Uncertain Income: Backorders create uncertainty around future income because it’s unclear when customers will receive their orders and make payments. This uncertainty makes it challenging for companies to forecast their cash inflows accurately, making it harder to plan for expenses or make strategic business decisions.

Impact on Cash Flow: Backorder fulfillment often requires additional resources, such as rush orders, overtime production and expedited shipping. This leads to extra costs, affecting the company’s profit margins. The longer it takes to fulfill an order, the longer the company waits to receive payment for those products. Additionally, if backorders become chronic, they can disrupt your cash flow, making it difficult to pay suppliers or invest in growth initiatives.

Customer Dissatisfaction: Customers demand their products be delivered within a reasonable timeframe. If their orders are delayed due to backorders, you risk losing them. Dealing with customer frustration and complaints due to backorders can demotivate employees, impacting productivity and morale.

Backorders Best Practices

While it is difficult to eliminate backorders faced by businesses completely, there are a few ways that can be implemented to manage and reduce the impact of backorders:

Demand Forecasting

- Use the ARIMA modeling technique to analyze historical sales data and market trends to predict future demand accurately.

- Collaborate closely with stakeholders to gain insights into customer preferences, market trends, and marketing activities that may impact demand.

- Use robust forecasting techniques (predictive analytics and machine learning algorithms) to improve forecast accuracy and determine demand patterns.

Real-Time Visibility

- Implement a real-time visibility platform to gain insights into inventory levels and proactively prevent backorders.

- Invest in real-time transportation visibility platform to enable real-time tracking in a repeatable manner and freight forwarders of a network of highly rotating carriers.

Inventory Optimization

- Maintain optimal inventory levels by establishing inventory management techniques such as just-in-time (JIT) inventory and safety stock planning.

- Perform ABC Analysis and leverage inventory management systems to track inventory levels in real-time and monitor stock movements.

- Conduct inventory audits to review inventory turnover rates, lead times, and reorder points to ensure efficient inventory replenishment and avoid stock shortage.

Supplier Collaboration

- Build strong relationships with key suppliers to reduce lead times and ensure OTIF.

- Integrate your suppliers at an early phase of its new product development.

- Communicate forecasted demand and stock requirements to suppliers to facilitate proactive production scheduling and stock replenishment.

Streamlined Order Fulfillment Processes

- Utilize order management systems and enterprise resource planning (ERP) software to centralize order processing, shipment tracking, and inventory management.

- Establish a responsive system to manage when demand exceeds supply and some orders cannot be fulfilled.

- Monitor KPIs such as backorder rate, fill rate, and order cycle time to assess supply chain performance and identify improvement areas.

How Quloi can Help In Improving Your Backorder Performance

Quloi helps businesses reduce backorders by streamlining production processes and managing supplier relations.

- Facilitate real-time communication and collaboration between buyers and suppliers, enabling proactive order management

- Improve visibility into production schedules, supplier inventory levels, and lead times, allowing for inventory optimization

- Integrate Quloi with your existing tools (ERPs, TMS, WMS, and other supporting logistics tools) for a unified workflow

- Track the movement of goods from suppliers to customers, minimizing stockouts and ensuring smoother order fulfillment

- Maintain information and system integrity through audit trails

Backorders Got You Down? Schedule a Free Consultation with Our Supply Chain Experts.

Related Articles