Solutions for Supply Chain Challenges in the Paper Industry

The pulp and paper manufacturing industry, a behemoth on its own, is more than just a contributor to the global economy. While we narrow our focus to the everyday use of paper, the industry’s significance is beyond it, boasting a staggering value of approximately $266.4 billion. As a driver of local economies and a beacon of innovation, the paper industry still grapples with unique challenges, as discussed in the first post of this blog series. Let’s discuss how Quloi’s supply chain visibility and collaboration platform can help paper manufacturers.

Leverage Supply Chain Visibility Tools

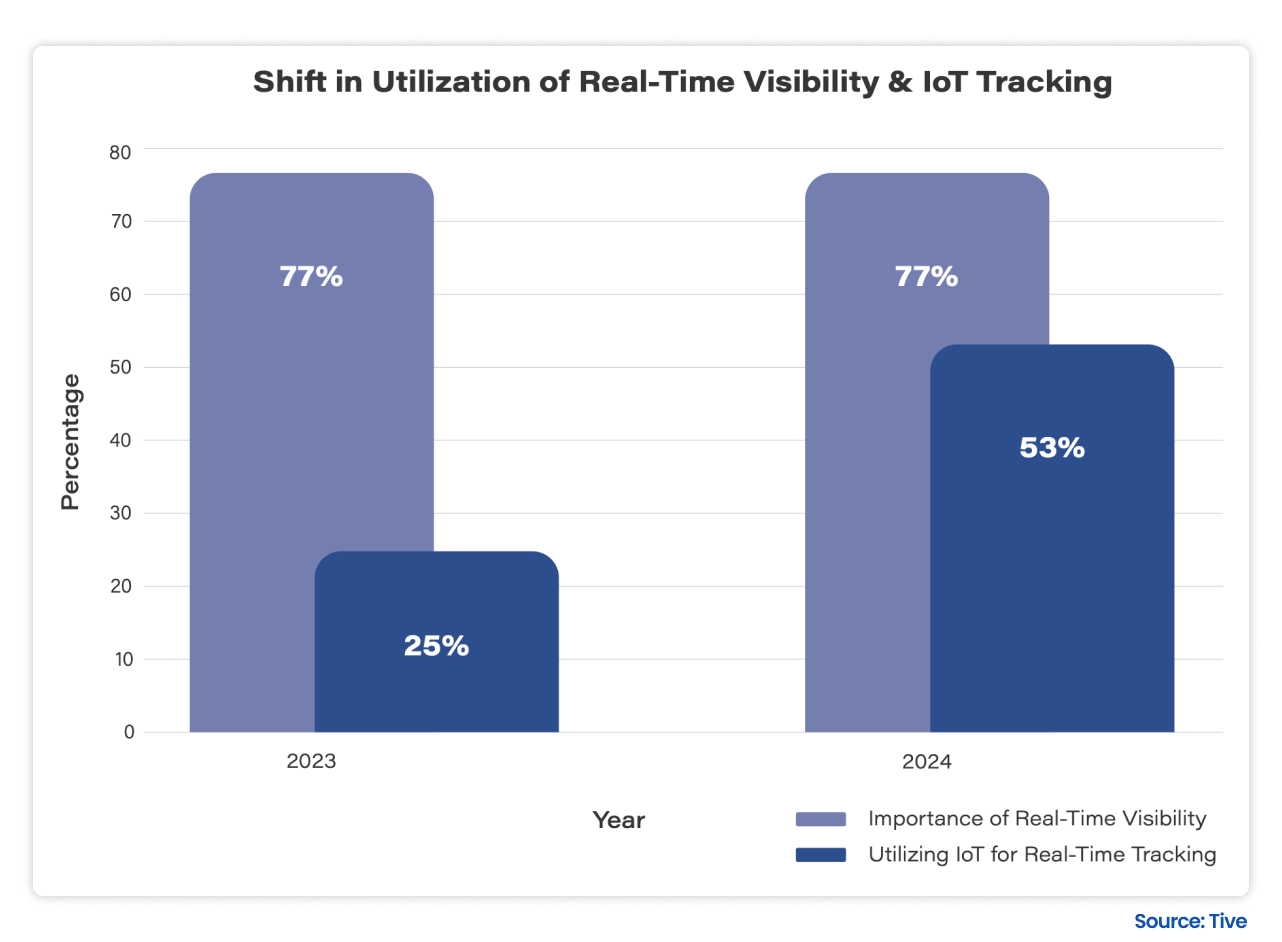

Real-time visibility has become a necessity and desire in supply chain and logistics. The 2024 survey data reveals that only 53% of companies utilize IoT devices/trackers for real-time shipment tracking. Notably, this has increased from 25% in 2023, emphasizing the importance of real-time visibility. Adopting digital platforms and IoT technologies helps meet customer demands and gain operational efficiency by tracking inventory, shipment, and production processes. Quloi enables real-time tracking of purchase orders (POs) and shipment statuses. This ensures paper manufacturers have visibility into every stage, from PO approval to delivery – allowing them to proactively identify bottlenecks and address delays.

Logistics Optimization

Paper manufacturers can optimize transportation, consolidate shipments, and minimize freight costs by collaborating with freight forwarders and logistics providers. Real-time visibility into shipment status and delivery times ensures paper manufacturers that raw materials and finished products reach their destinations on time in full. Utilizing a transportation management system that integrates with the supply chain platform allows paper manufacturers to track shipments and monitor fuel efficiency, lowering transportation costs. By enabling real-time visibility into shipment movements and delivery statuses, Quloi facilitates proactive logistics operations management and ensures on-time, in-full (OTIF) deliveries. The platform also supports multiple modes of transportation (road, air, ocean) to shippers to ensure successful last-mile deliveries.

Compliance Management

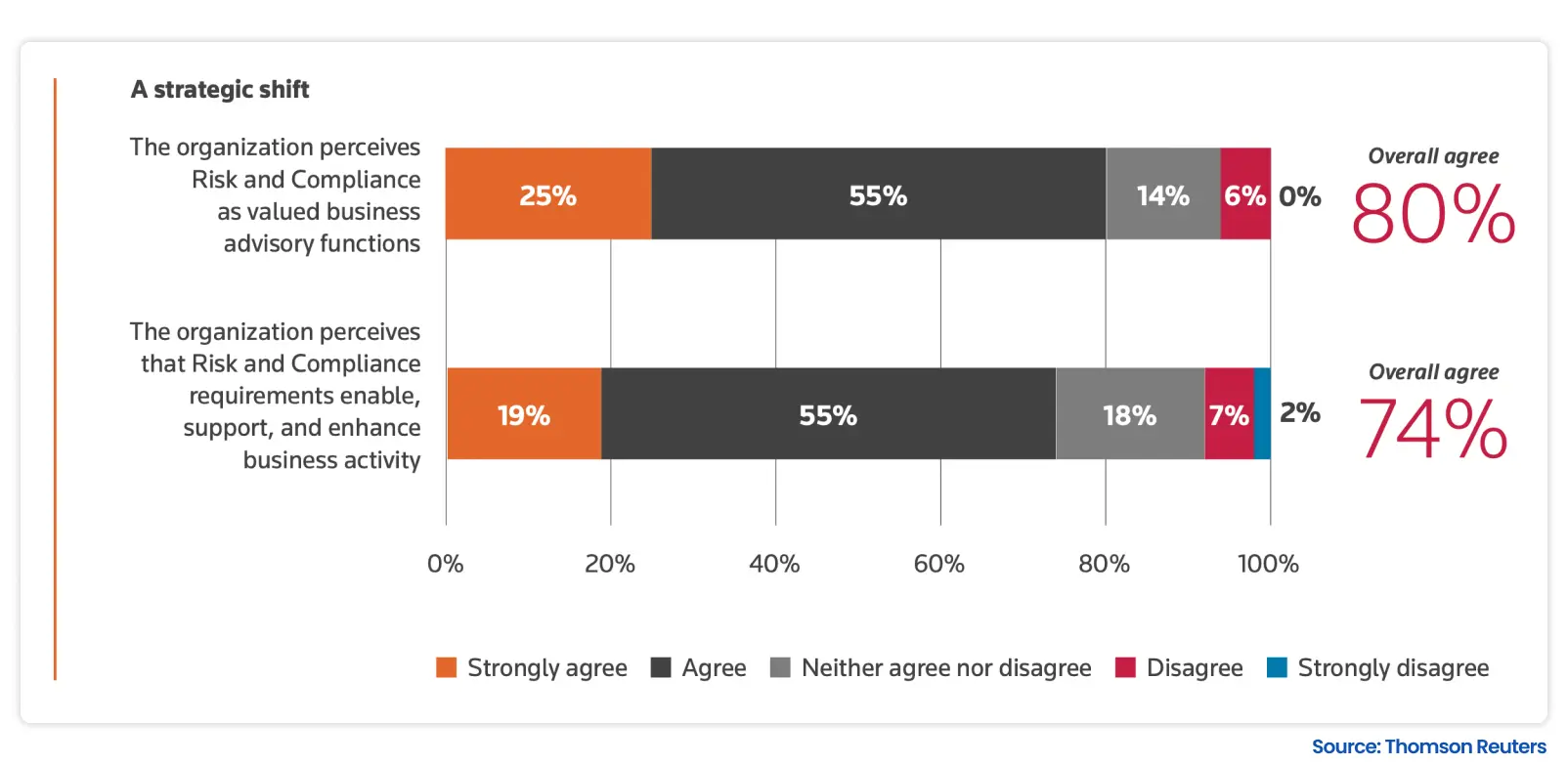

Data security compliance is vital for a business to run efficiently. According to the 2023 Thomson Reuters Risk & Compliance Survey Report, 80% of corporate risk and compliance professionals acknowledge that their organizations consider risk and compliance valuable business advisory functions. Additionally, 74% of companies believe that adhering to risk and compliance requirements facilitates, supports, and enriches business operations. Organizations must prioritize conducting regular audits and providing suppliers with training on regulatory requirements and best practices.

Technology Investment

Technology development heavily influences the future growth of the paper industry. In 2023, wood-based technology contributed around $271.2 billion to the global pulp and paper industry. This significant contribution is forecast to increase in the subsequent years, reaching around $304.6 billion in 2031. Companies that embrace technologies like IoT-enabled devices, automation, robotics, and AI-based predictive analytics will likely offer unique value propositions to customers.

Supplier Collaboration

Collaboration in the paper industry enables a more stable and resilient supply chain. Multiple pulp suppliers working closely can ensure a reliable and consistent source of raw materials and resources, leading to higher efficiency and reduced costs. With tools to seamlessly track communications and a knowledge base for suppliers, Quloi, a supplier management platform, reduces manual interventions and ensures timely information delivery. The platform facilitates seamless communication between paper manufacturers and pulp suppliers, enhancing productivity and innovation. The platform also helps paper manufacturers manage and store supplier information centrally to increase relationship transparency.

Supply Chain Integration

Integrating all aspects of the supply chain – from procurement and production to distribution and customer delivery into a cohesive and interconnected system has become necessary. This integration facilitates data exchange across departments and stakeholders, enabling data-driven decision-making and proactive problem-solving. For example, paper manufacturers can gain a holistic view of the supply chain by implementing a unified platform that connects ERP systems, manufacturing operations, and logistics networks. This enables paper manufacturers to respond quickly to changing market demands and supply chain disruptions.

Sustainability Practices

The paper industry greatly affects forests, water resources, and carbon dioxide emissions. Efficient management of purchase orders (PO) and shipments through integrated supply chain systems allows paper manufacturers to optimize resource use and minimize waste. For instance, AF&PA members have reduced greenhouse gas (GHG) emissions by over 24%. They are committed to reducing GHG emissions by 50% by 2030 and promoting a more sustainable future for the industry. Achieving FSC (Forest Stewardship Council) certification demonstrates a commitment to resource efficiency, waste reduction, and sustainability – enhancing credibility and market competitiveness.

Bet for a Transformational Change with Quloi

The global paper industry contributes significantly to the overall health of the economy. With a strong presence in almost every region, the industry faces its own set of challenges. Quloi, a tech-powered supply chain collaboration and visibility software, helps paper manufacturing companies combat the critical challenges and issues they face. The end-to-end, real-time visibility software helps manufacturing companies improve supply chain resilience and position themselves for success in a competitive business landscape.

Why Choose Quloi?

- Ensure timely delivery of raw materials through real-time tracking of PO statuses.

- Minimize transportation delays by proactively managing logistics operations.

- Streamline cargo logistics planning with instant quotes and booking confirmations.

- Integrate with existing ERP systems to ensure data consistency.

- Leverage supplier scorecards to evaluate reliability and optimize supplier relationships.

- Improve document accessibility and organization through centralized document management.

- Enhance team collaboration and productivity through dedicated workspaces.

- Facilitate seamless communication among teams through Slack/Teams integration.

Ready to navigate supply chain challenges facing your organization?

Get a FREE consultation on how Quloi can effectively help your paper mill manage multiple pulp suppliers.