Types of Supply Chain Integrations to Drive Your Supply Chain Forward

Imagine a bustling warehouse, filled to the brim with products waiting to be shipped. The orders are pouring in, but the systems are disjointed, communication is scattered, and efficiency is decreasing.

Sounds familiar?

Now, let’s dive deeper. How do you ensure seamless communication and information sharing between your procurement team and suppliers? How do you prevent product shortage and maintain optimum inventory levels? Most importantly, how do you keep up with the ever-changing customer demand?

Many organizations face similar challenges. Warren Buffet, the legendary investor, once said, “Price is what you pay. Value is what you get.” It conveys the essence of supply chain integration – extracting maximum value from every link across the supply chain. But why does integration matter for businesses? Why are integrated supply chains the cornerstone of modern business success? Let’s learn the concept of integrated supply chains and why organizations cannot afford to overlook the potential of supply chain integration.

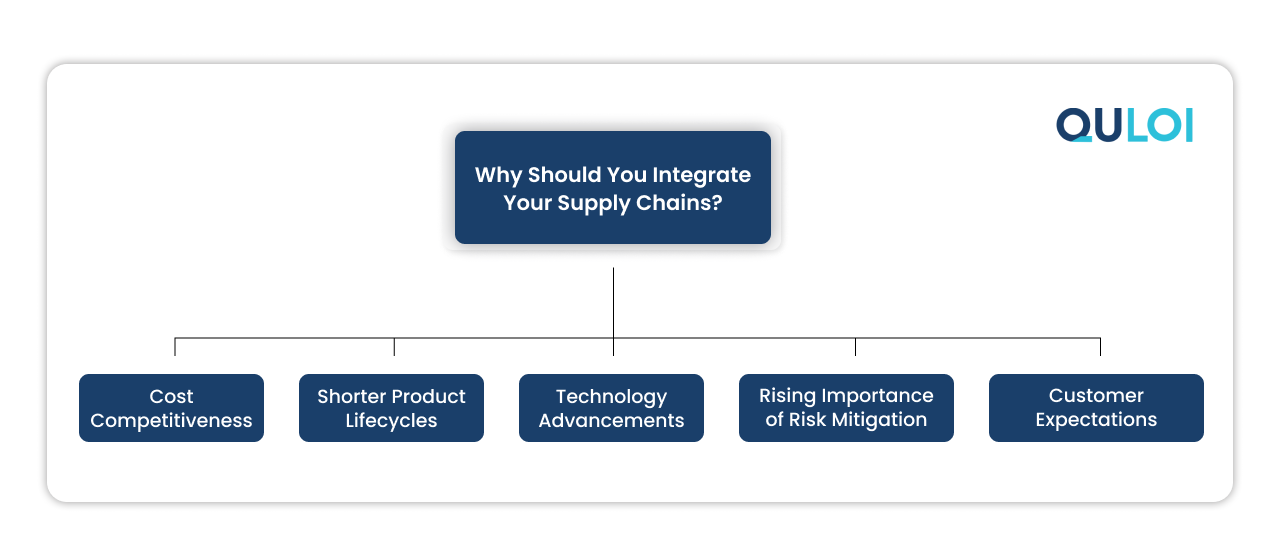

Why should you Integrate your

Supply Chains?

Cost Competitiveness: With integrated systems and processes, businesses can eliminate inefficiencies and optimize resource utilization, reducing procurement, transportation, and inventory management costs. This leads to improving profitability and competitiveness.

Shorter Product Lifecycles: Customers are eager to try the latest products. However, with evolving customer expectations, the products popular today might be forgotten tomorrow. Supply chain integration helps stakeholders communicate and work closely to accommodate varying product lifecycles and keep up with changing trends and customer preferences.

Technology Advancements: With the emergence of digital technologies, supply chain stakeholders can connect and share real-time information. The integrated and connected systems facilitate direct communication between buyers and suppliers, enabling improved transparency, faster decision-making, and greater agility in responding proactively to market dynamics.

Globalization: With businesses operating in a global marketplace, sourcing materials, components, and finished products from diverse regions becomes complex. Integrated supply chains help manage this complexity by ensuring efficient supplier collaboration. This leads to optimized sourcing, production, distribution, and delivery processes across borders.

Customer Expectations: The increasing demand for super-fast delivery has made same-next-day capabilities a necessity rather than a choice. Supply chain integration enables companies to collect and analyze customer data effectively, ensuring personalized products tailored to their specific needs on time.

Barriers to Supply Chain Integration

Inconsistent Data: Data stored in different formats, structures, or quality across different systems often cause errors during data exchange and analysis. When important data is overlooked or not captured fully, it derives incomplete insights and poor decision-making. For example, product details or quantity measurement variations can lead to discrepancies in inventory records or pricing, increasing lead times and affecting order fulfillment and financial reporting accuracy.

Resistance to Change: Change often involves uncertainty, like disruptions to existing work processes, job roles, or relationships with business partners. Resistance to change due to unfamiliar job responsibilities and increased workloads can impede integration. It can undermine collaboration, teamwork, and willingness to adapt to new ways of working – preventing innovation and affecting supply chain performance.

Supplier and Partner Collaboration: Suppliers and partners may have different goals and expectations than the organization implementing the integration initiative. Misalignment in goals and objectives due to limited communication can lead to conflicts in reaching a consensus on key business decisions. Cultural differences and different languages further hinder communication and cooperation, disrupting the supply chain.

Legacy Systems: Legacy systems often use outdated programming languages and architectures, lacking interoperability and compatibility with modern technologies. They also lack functionalities such as visibility, real-time tracking, and automation capabilities, limiting the organization’s ability to optimize operations and adapt to changing market trends.

Security Concerns: Interconnected and digitized systems entail the exchange of confidential business information, such as financial data, customer details, and product designs, among various stakeholders. Inadequate security measures impose the risk of data breaches, exposing sensitive information to unauthorized access or theft.

Systems You can Integrate in Your

Supply Chain

Enterprise Resource Planning (ERP): ERP systems provide a centralized platform for managing core business functions such as production planning, procurement, and inventory. Integrating ERP systems with other supply chain applications enables seamless, real-time data exchange and synchronization. It also facilitates visibility into key metrics and collaborative decision-making across the organization.

Supplier Relationship Management (SRM): SRM systems are designed to manage their relationships with suppliers across various supply chain stages. This includes sourcing, procurement, contract management, performance evaluation, etc. By implementing SRM integration practices, organizations can analyze supplier performance based on seamless data exchange between SRM and other systems, detect and mitigate risks, and identify process improvements and cost savings opportunities. SRM integration fosters greater efficiency throughout the supply chain, ultimately driving business success.

Communication Channels (Microsoft Teams, Slack): Communication tools like Slack and Microsoft Teams facilitate communication among supply chain stakeholders. These platforms improve communication flow, streamline decision-making processes, and promote cross-functional collaboration when integrated with other supply chain systems. By enabling a centralized platform for sharing information, documents, and innovative ideas, these communication channels help organizations stay agile and competitive.

Customs Broker Integration: Customs brokers facilitate the clearance of goods through customs checkpoints, ensuring adherence to import and export regulations. By integrating customs broker systems into the supply chain, businesses can expedite customs clearance processes, reduce delays at border crossings, and minimize the risk of fines or penalties for non-compliance. This integration enhances visibility into customs procedures, simplifies documentation requirements, and fosters smooth cross-border trade operations.

Freight Forwarder (FF) Integration: Freight forwarders organize shipments by coordinating the transportation of goods between suppliers, manufacturers, and customers. With Freight Forwarder integration into the supply chain, organizations can streamline freight booking and tracking processes, optimize routes, and enable timely delivery of goods. Moreover, this enhances visibility into shipment status, minimizes transit times, and reduces transportation costs – ultimately improving overall supply chain efficiency.

Warehouse Management System (WMS): WMS systems help organizations optimize warehouse operations, including inventory management, order picking, and shipping. WMS integration helps businesses enhance inventory accuracy, minimize labor costs, and increase order fulfillment efficiency. By integrating WMS systems into supply chains, businesses can optimize storage space utilization, track real-time inventory movements, and improve overall warehouse productivity.

Customer Relationship Management (CRM) Systems: CRM systems help businesses manage and nurture customer relationships throughout the sales cycle. CRM integration improves customer segmentation and order management. Organizations can leverage data from CRM systems and tailor their supply chain strategies to cater to unique customer needs.

Integrate Your Supply Chain with Quloi

Real-Time Collaboration: Utilize the Quloi platform to confirm orders and updates electronically, communicate directly to clarify details, receive status updates, and resolve any issues.

Centralized Workspaces: Provide dedicated workspaces for collaborative tasks like sharing PO details (including lead time, packing, and delivery instructions) with your supplier. Facilitate easy retrieval of essential documents, reducing time spent searching for information.

Automated Workflows and Notifications: Leverage the Quloi platform to automate tasks like sending reminders and notifications based on pre-defined triggers (e.g., notifications when an order nears its delivery date).

Real-Time Visibility: Gain real-time visibility to track order status, including confirmations, production updates, and shipment information.

Easy Supplier Onboarding: Simplify the supplier onboarding process, reducing administrative burdens and ensuring smooth integration into the platform.

Streamlined Order Management: Enable users to request modifications to purchase orders, ensuring PO process flexibility and reducing supplier errors or misunderstandings.

Related Articles